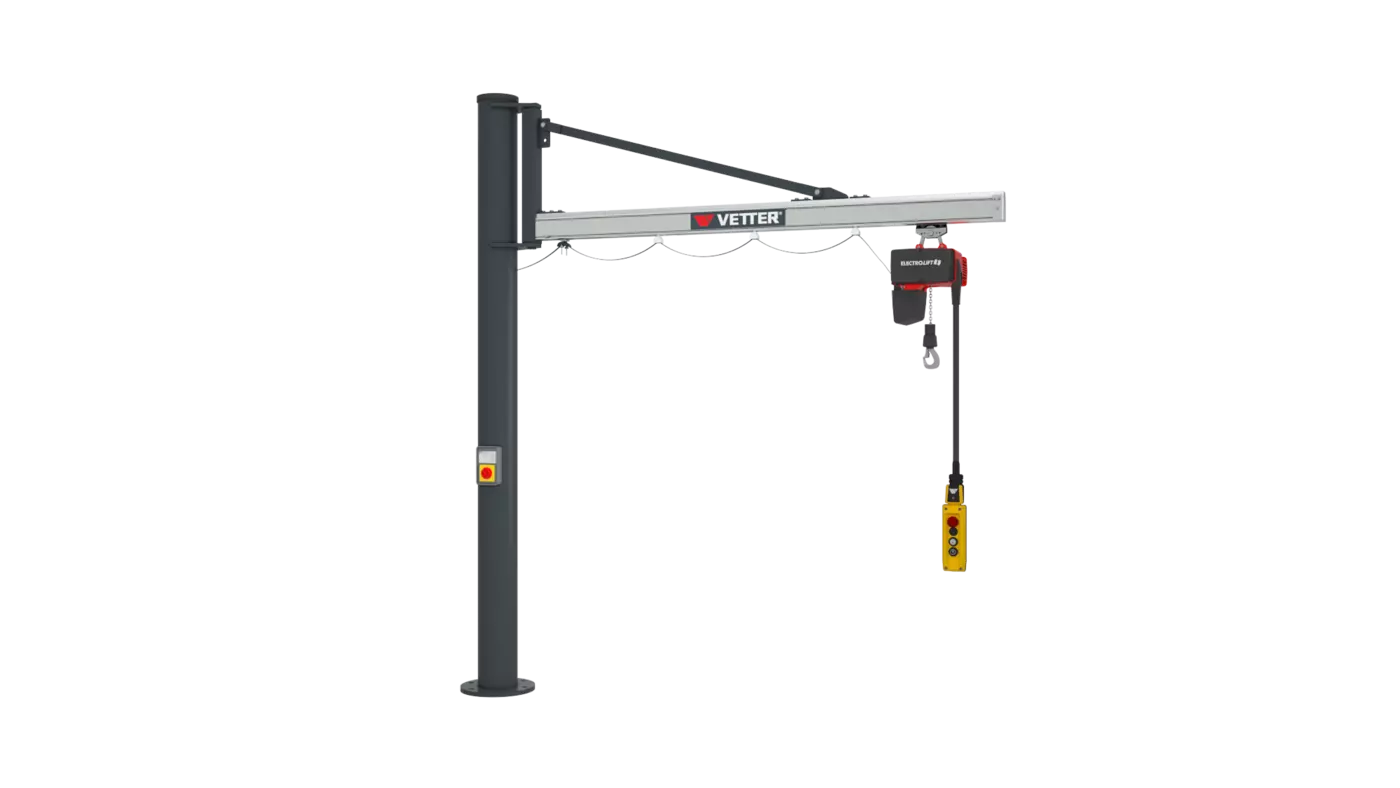

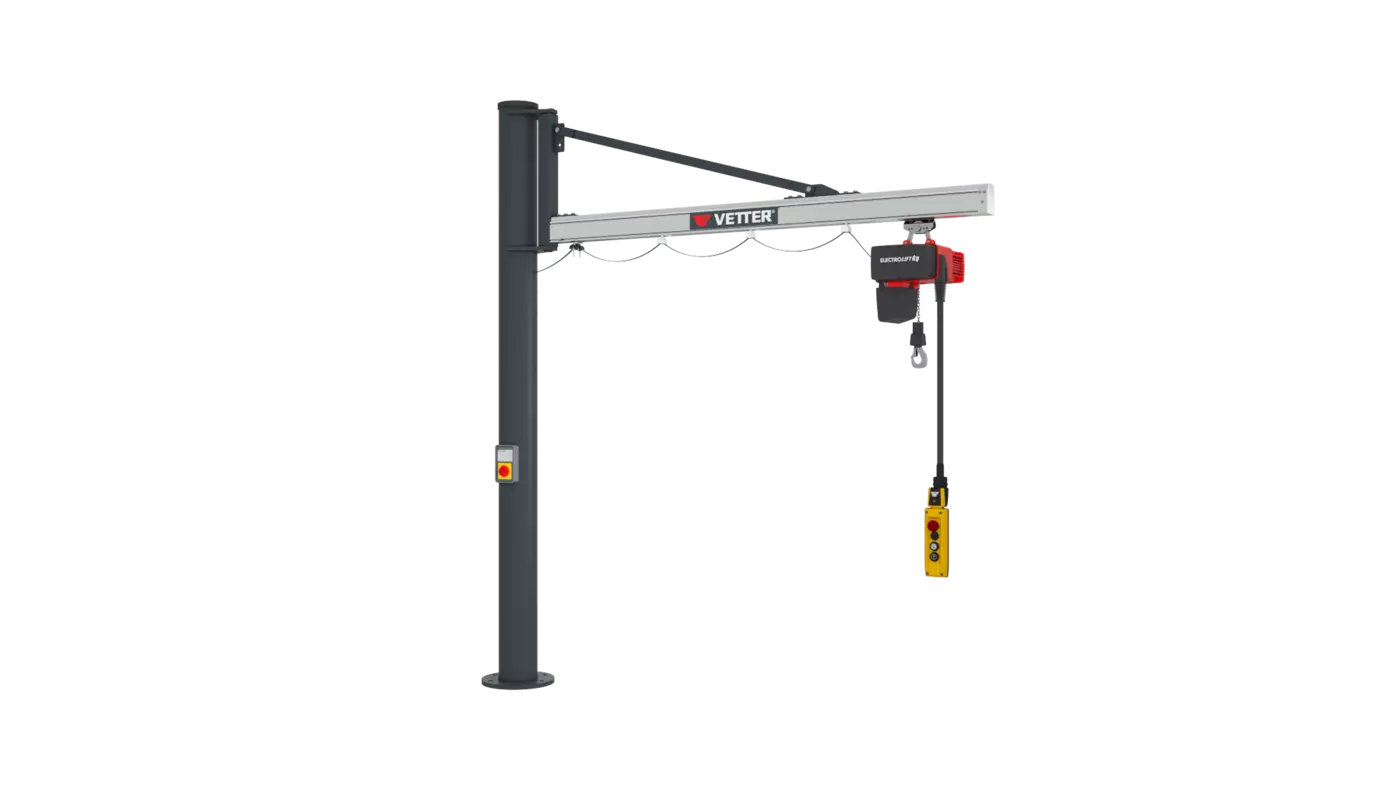

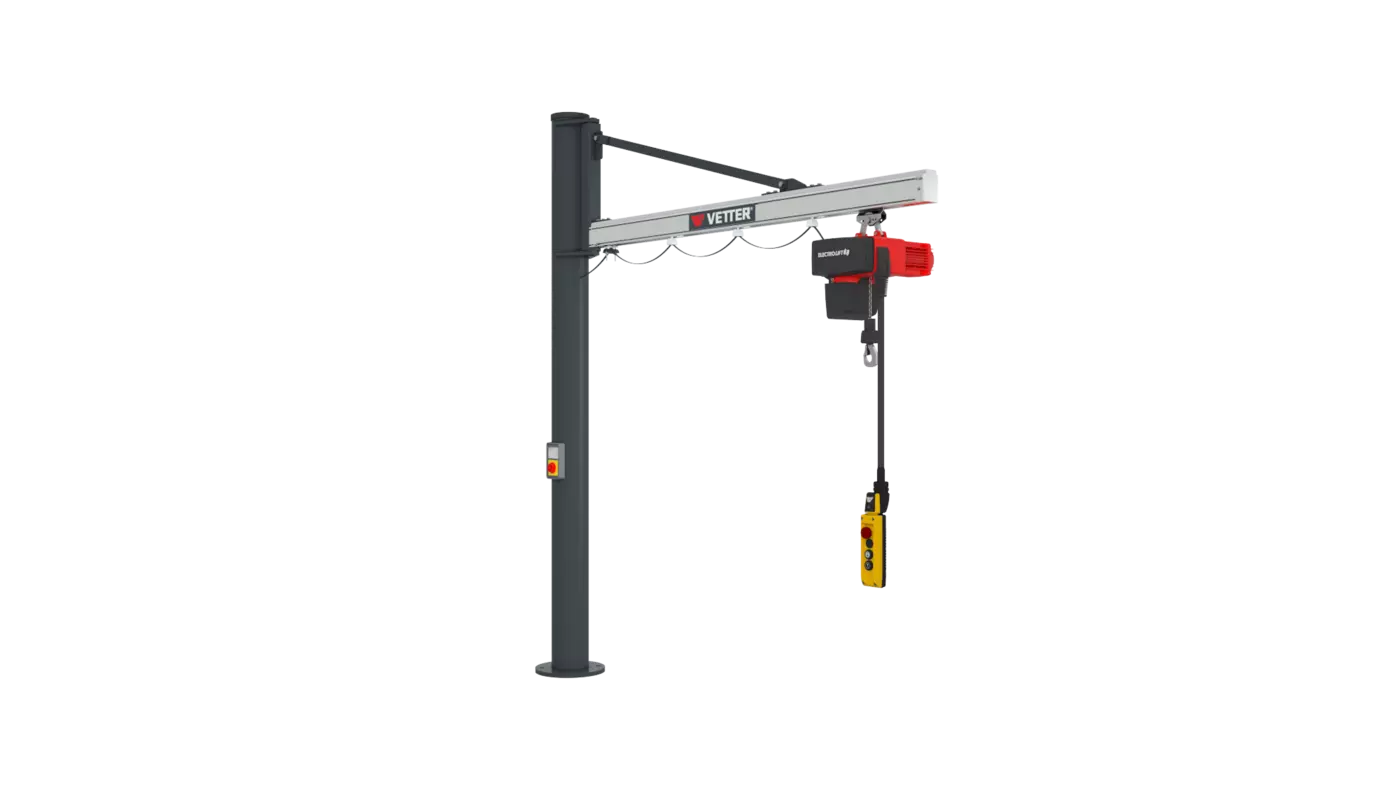

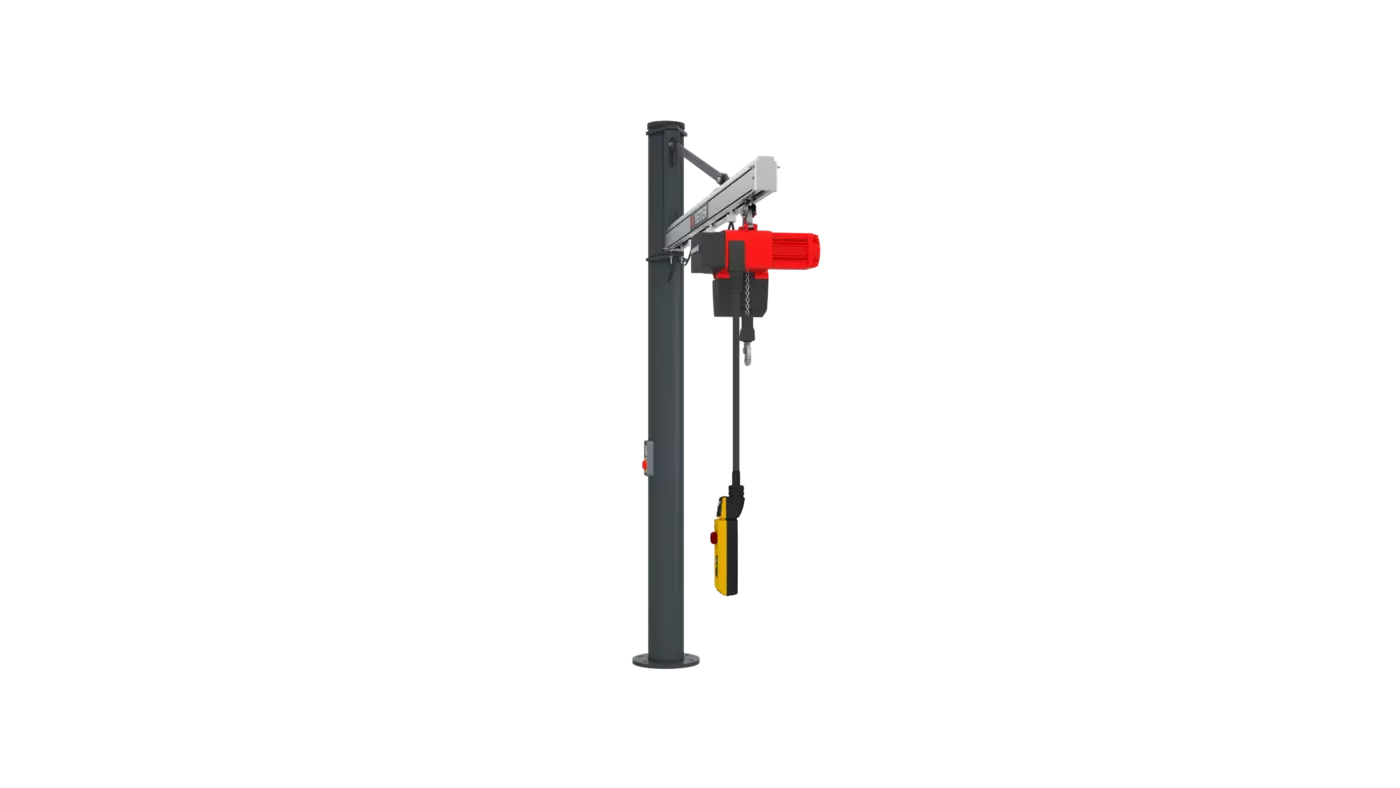

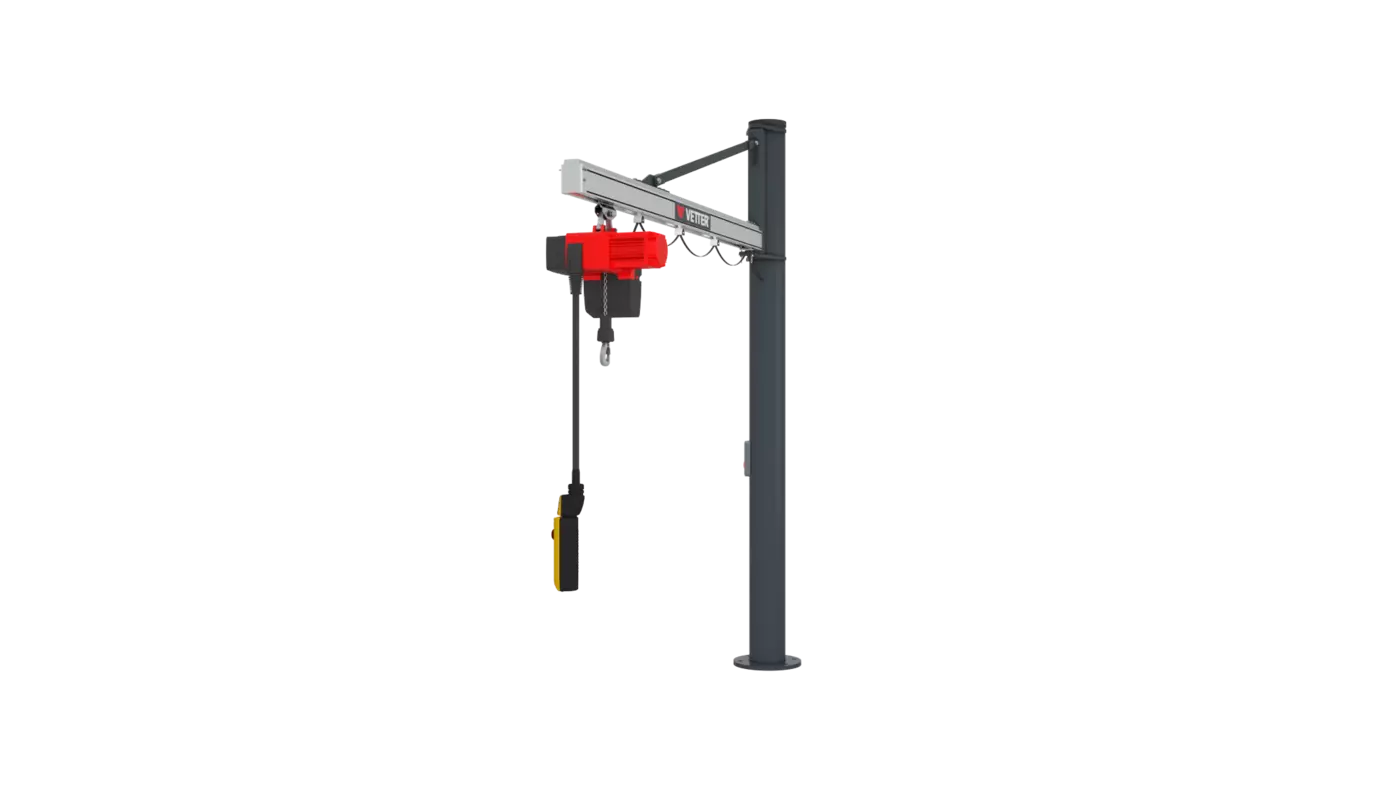

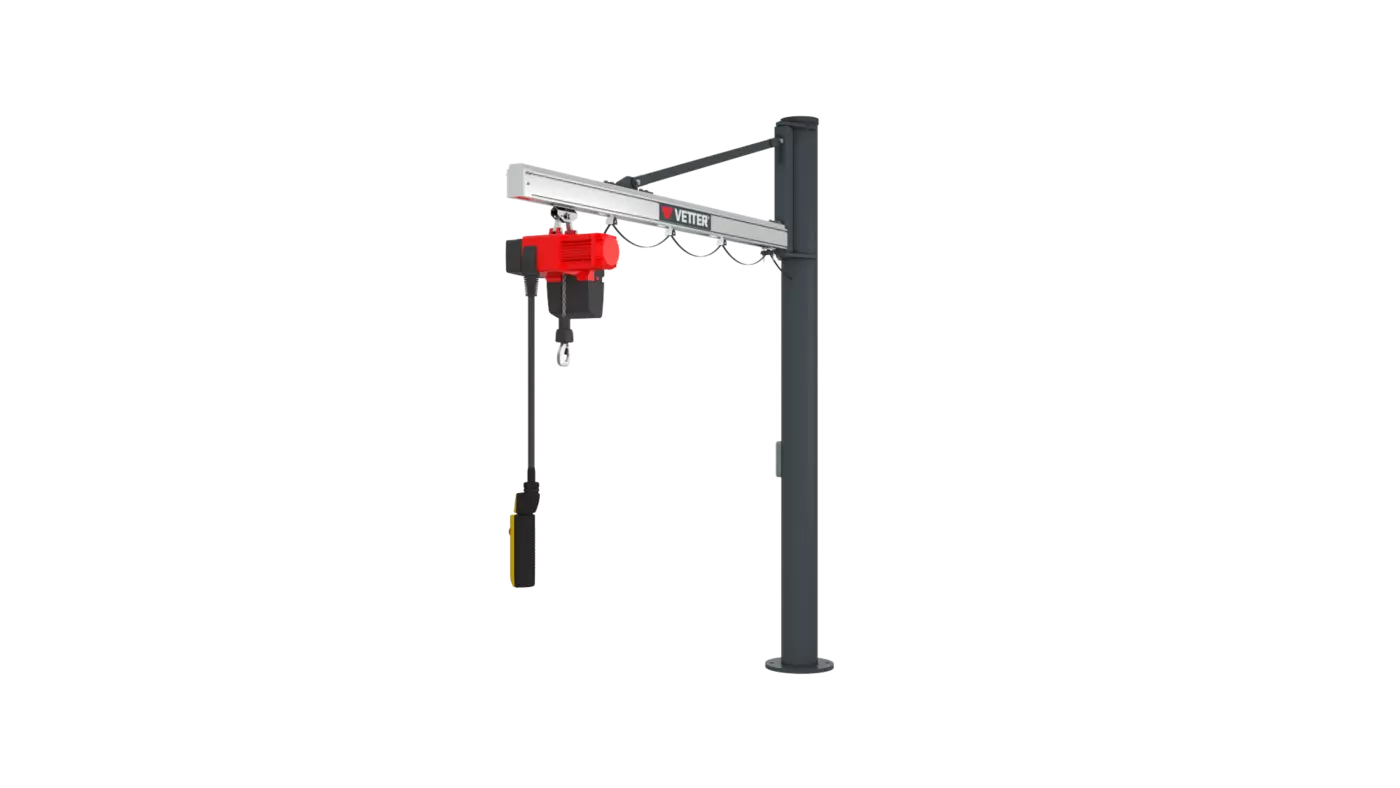

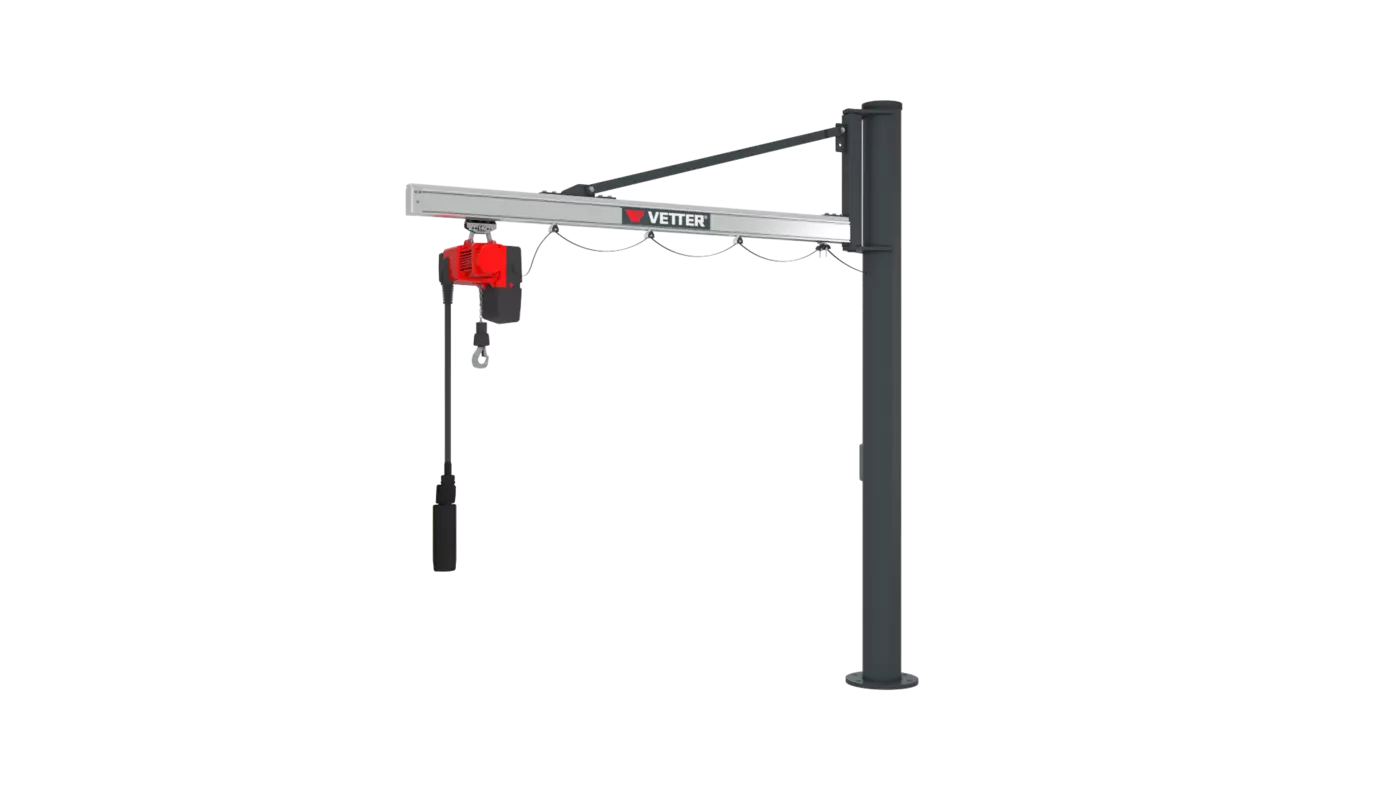

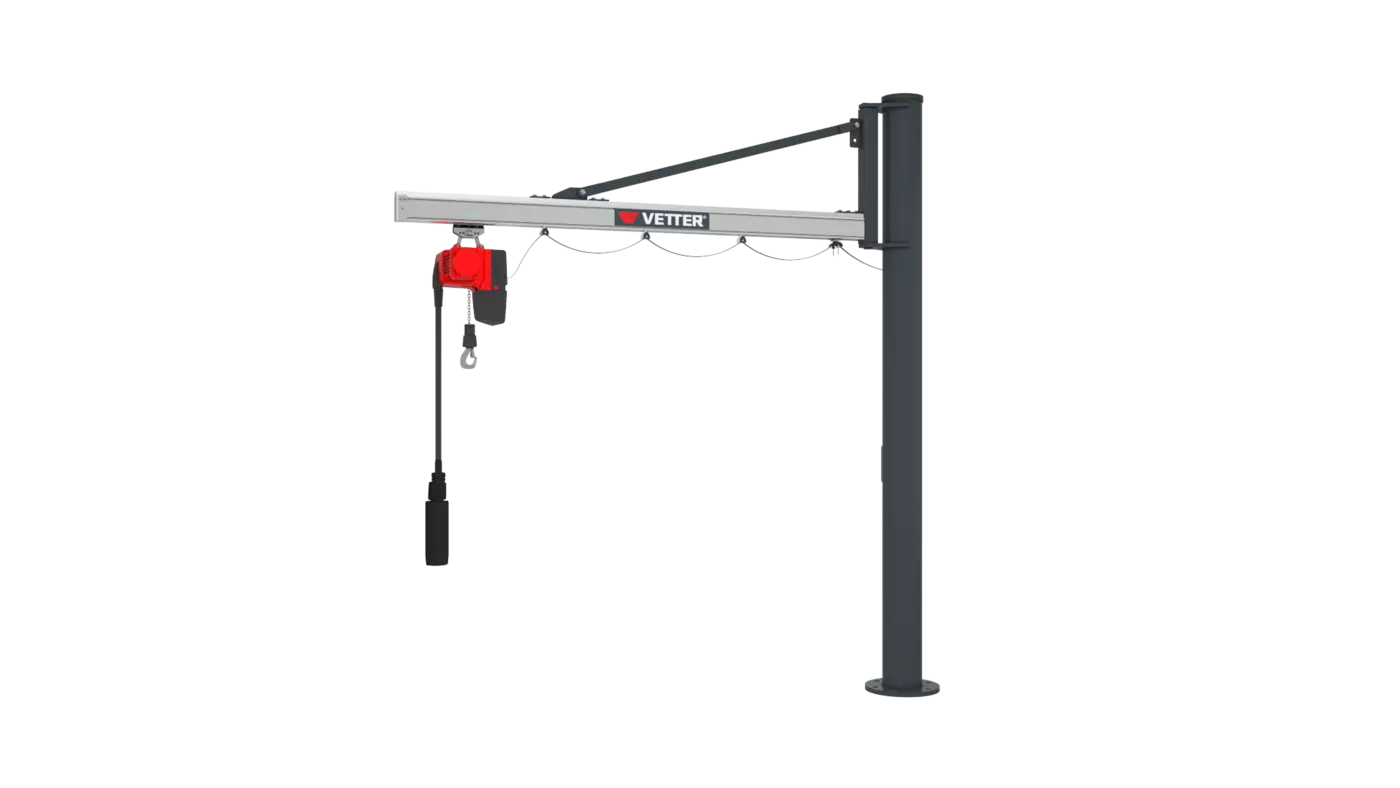

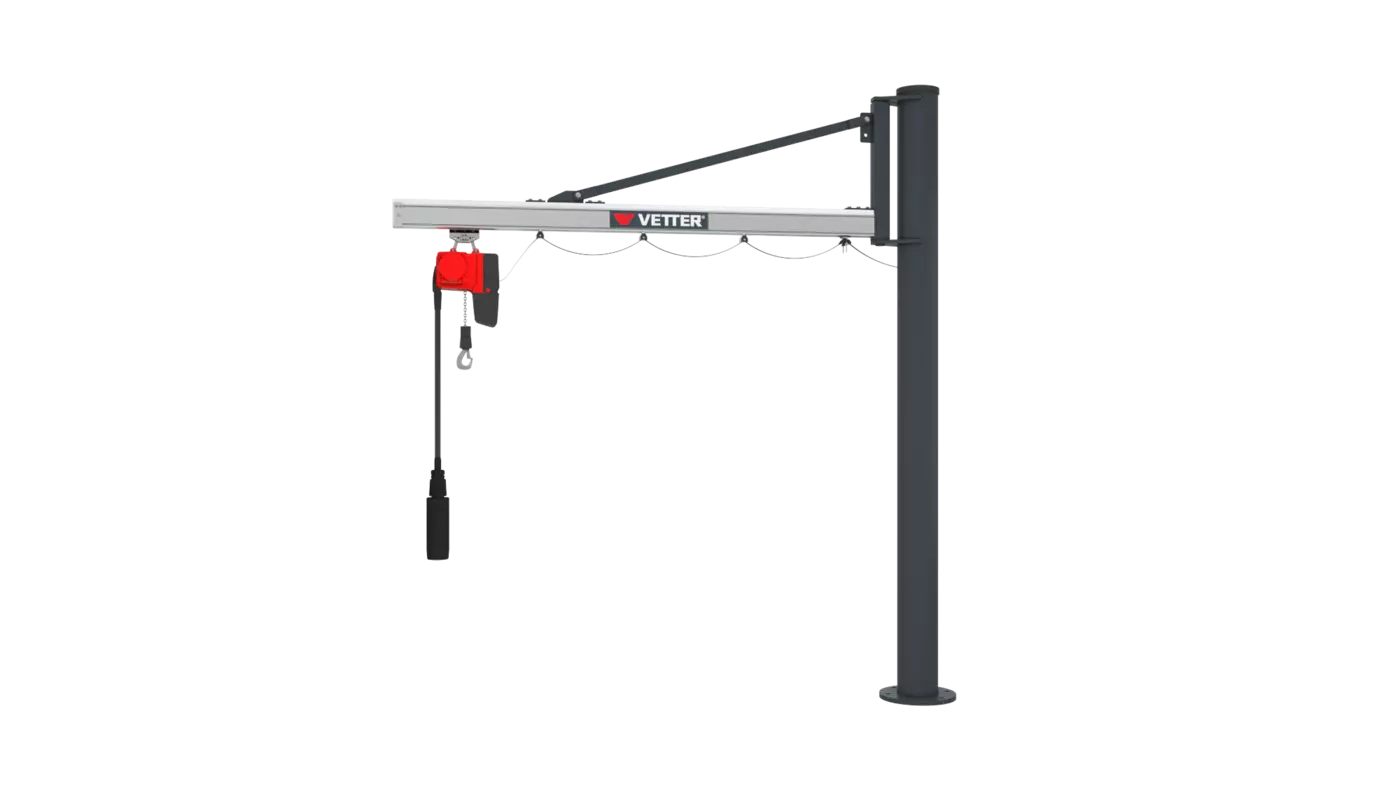

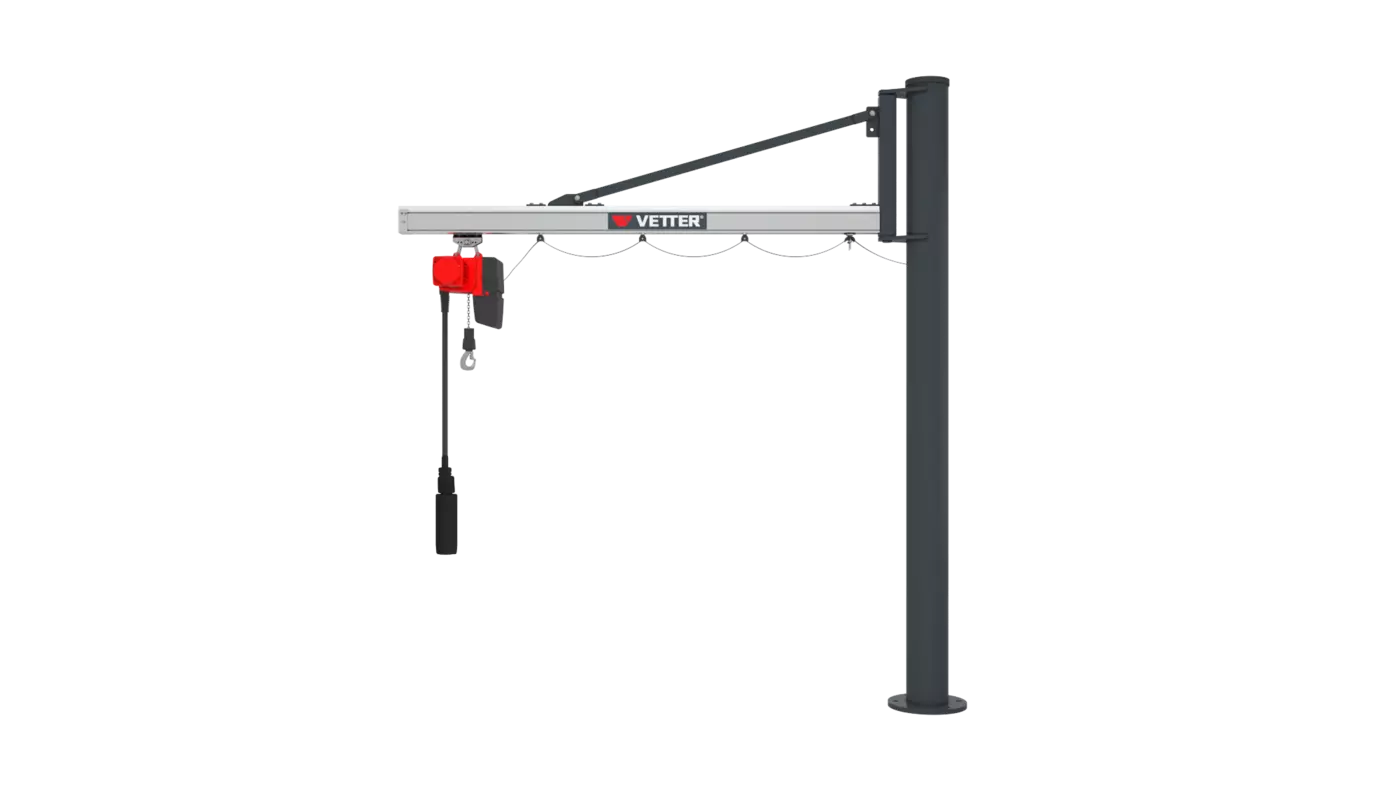

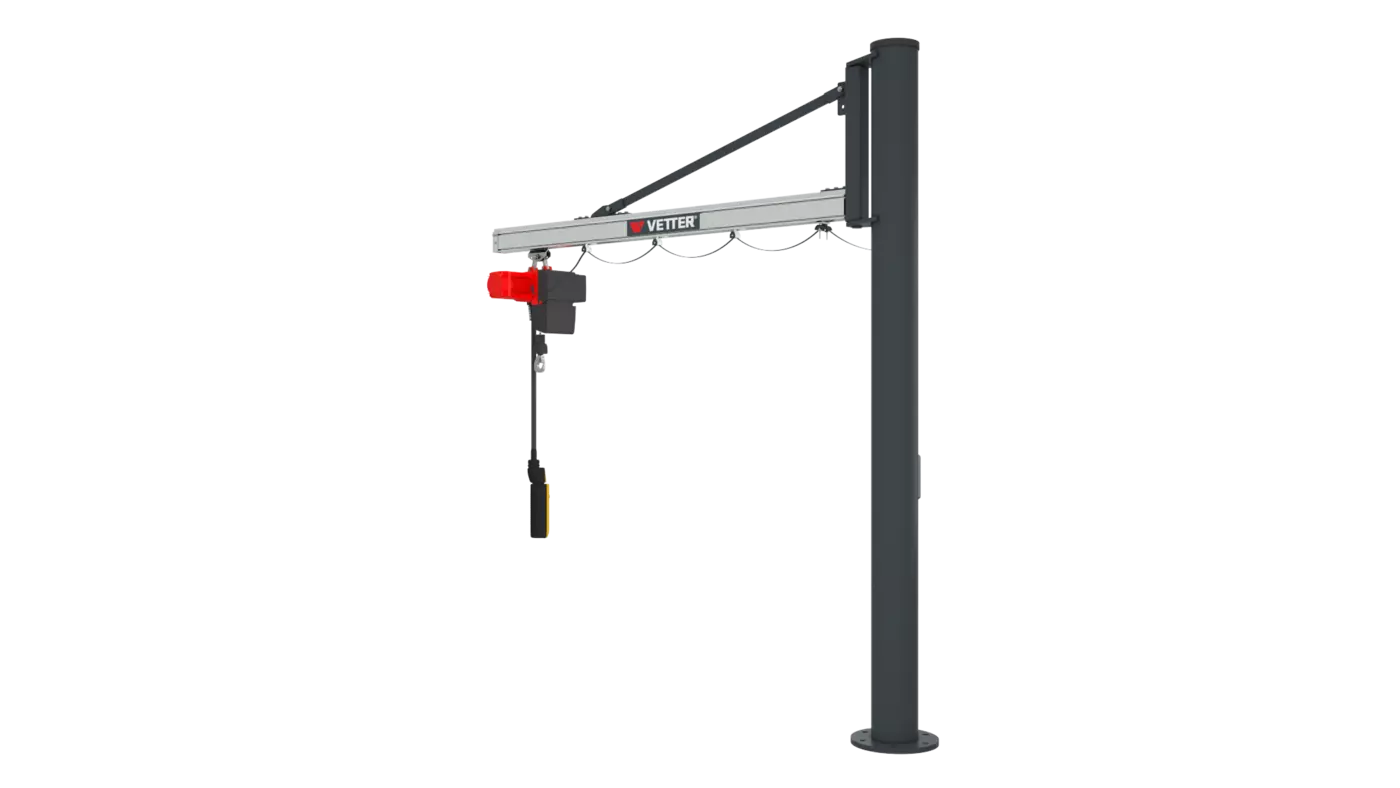

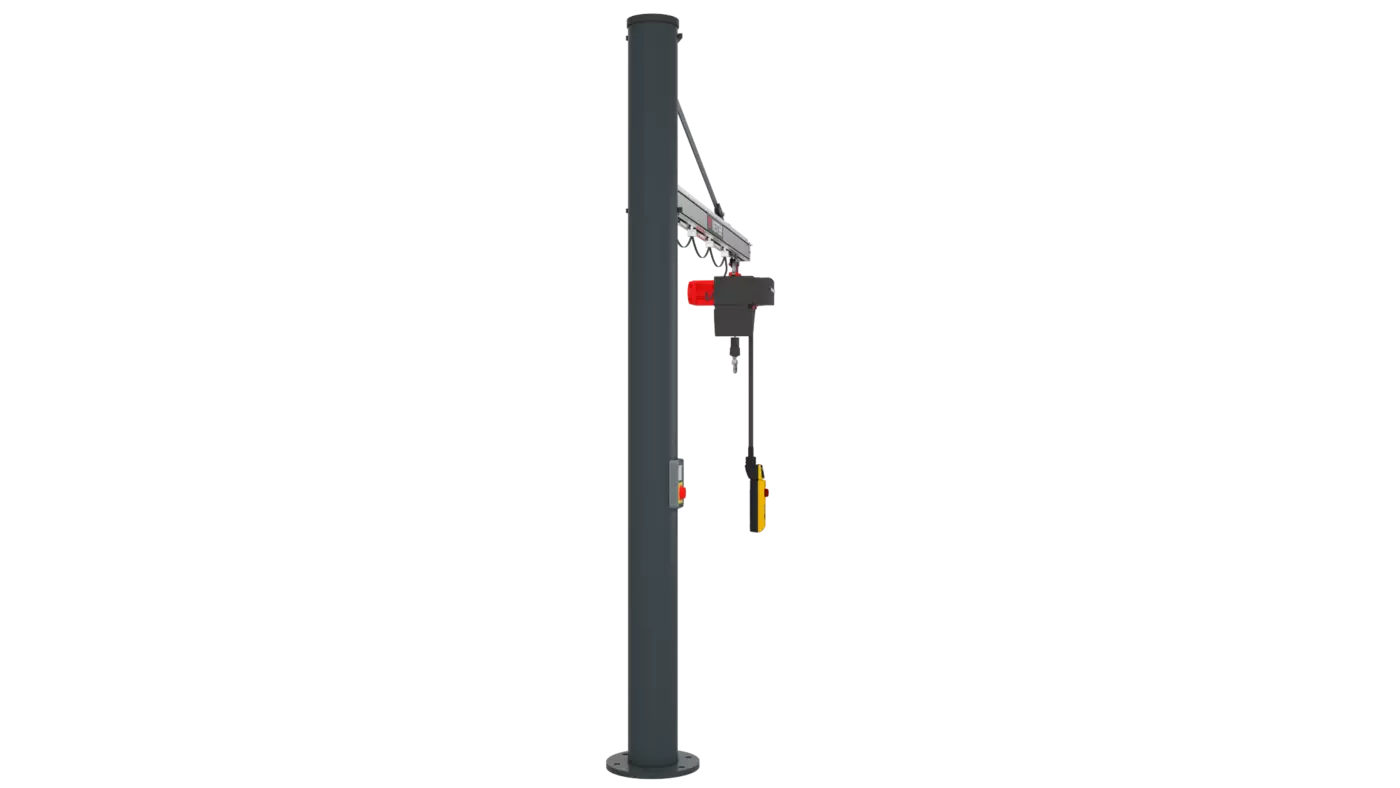

Column-mounted slewing jib crane

Type US

Tip The DowelPlate system VAS2 can be used to fasten the crane.

Product highlights

- Aluminium profile jib

- Ergonomic handling

- Easy slewing

- Smooth-running trolley

- Overbraced design, low dead weight of aluminium profile jib arm

- Trailing cable system travelling inside the aluminium profil

- Column height and jib arm length can be adjusted to conditions on the spot

- Easy to install thanks to dowelling on concrete floor (optional)

The easy-running one

The column-mounted jib arm crane US is a smooth-running crane with aluminium jib arm.

You can use it for easy, quick, and safe handling of small loads up to 500 kg; e.g. in logistics or automotive industry. Its overbraced design and lightweight aluminium jib arm enable especially easy slewing of the crane. Thanks to the good running qualities of the internal push trolley, the chain hoist moves quite easily. The handling crane UNILIFT perfectly meets your requirements since the column height can be adjusted individually.

Regarding fastening options, you can make your individual choice from comfortable dowelling on concrete floor using the patented VETTER DowelPlate system VAS2, fastening on foundation using anchors, TopAnchor, or CompactAnchor, and base flange for fastening on a steel structure.

Moreover, we offer ELECTROLIFT® chain hoists, slewing limit stops, and locking devices.

This type of slewing jib crane is also available as wall-mounted slewing jib crane.

Technical data

| Capacity: | 80 - 500 kg |

| Outreach: | 1900 - 5900 mm |

| Jib clearance: | 1895 - 5895 mm |

| Total height: | 2600 - 5250 mm |

| Slewing range: | 270° |

| EN 13001 Hoisting class: | HC2 |

| EN 13001 Stability class: | S2 |

| Jib design: | Overbraced |

| Slewing: | By hand |

| Hoist: | Electric chain hoist / Pulley block |

| Trolley drive: | By hand |

| Installation location: | Indoor |

Outreach [m]

Capacity [kg]

| 1.9 | 2.4 | 2.9 | 3.4 | 3.9 | 4.4 | 4.9 | 5.4 | 5.9 | |

|---|---|---|---|---|---|---|---|---|---|

| 80 | |||||||||

| 125 | |||||||||

| 250 | |||||||||

| 320 | |||||||||

| 500 |

3D-Ansicht

Accessories

Fastening

Dowels on existing concrete floor

DowelPlate system VAS2

The round solution for doweling the slewing crane on existing concrete floor. No complicated foundation work is necessary.

Anchorage with anchors

AnchorFix

The classical anchorage with anchors, temolate and a set of nuts and washers. Delivery also comprises a detailed foundation plan with information about foundation size and required reinforcement.

Anchorage without screws jutting out

TopAnchor

The alternative anchorage without screws jutting out (no trip hazards). The foundation area is kept free and accessible until the final intallation of the crane. The crane can be put into operation immediately, because no grouting is needed.

Anchorage with optimum ease of installation

CompactAnchor

This anchorage offers th advantages of TopAnchor an is furthermore very easy to install. There is no need to mount separete parts on site. Positioning in the foundation pit is easy done by set screws.

Fastening to steel structure or machine

Base flange, flush

Base flange, flush or plane machined surface, designed to attach the crane to a steel structure or machine. Fastening screws to be provided by the customer.

Other

Slewing limitation

Mechanical slewing limitation, can be installed and adjusted easily and continuously.

Locking device

For locking the jib arm in several positions. Applied by lever arm / traction rope (depending on crane

type) with control lever. Also to be used as immobilizer system up to wind force 7 Beaufort (only when crane is switched off and hoist is in idle position).

Surface finish

Paint system for indoor use US/UW

Cranes intended to be used in a hall are steel grit blasted and provided with a high-quality coating on the basis of corrosion category C2. It is suitable for minor atmospheric stress. The standard colour is daffodil yellow (RAL 7016) with a nominal layer thickness of 80 µm. The jib is finished in Aluminium anadised as standard.

Other RAL shades, corrosion categories, and layer thicknesses are available as an option.