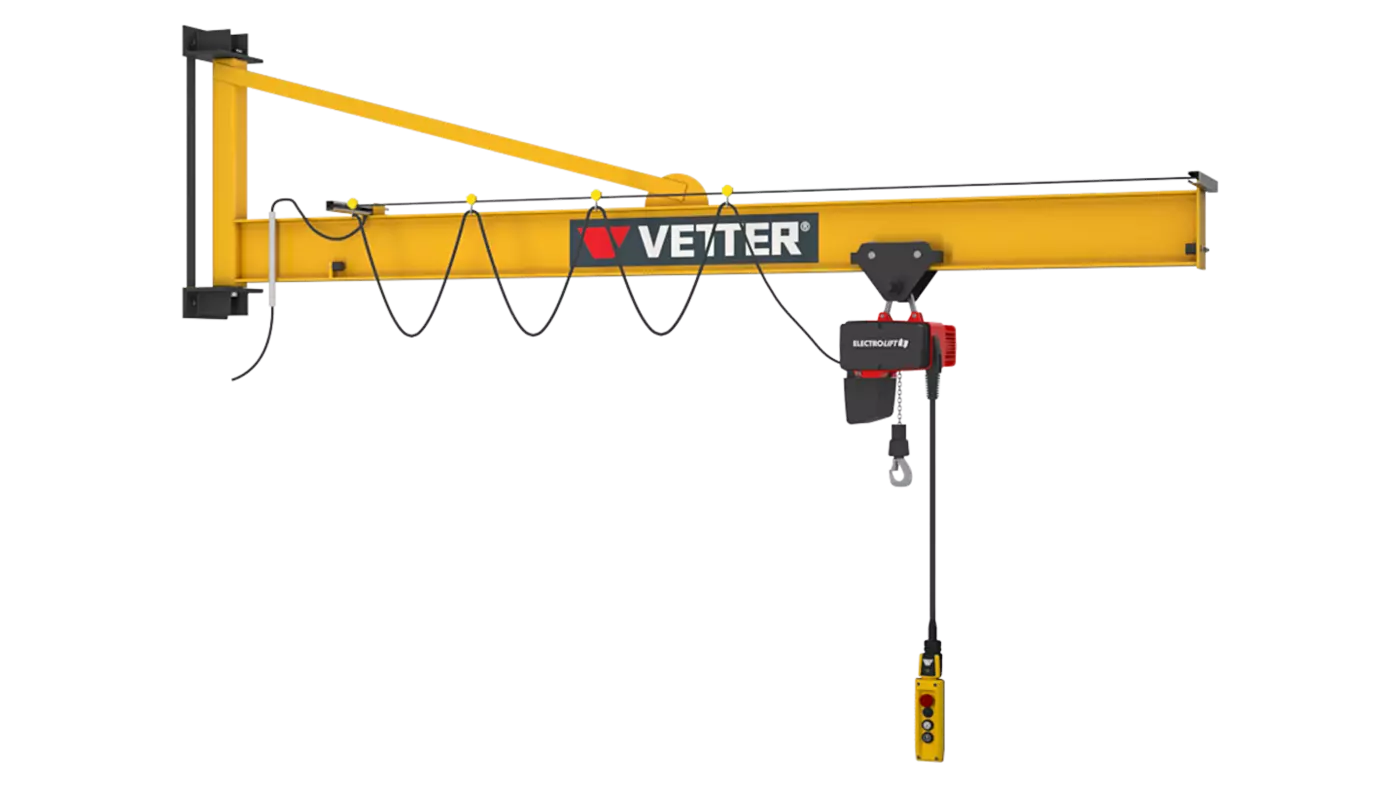

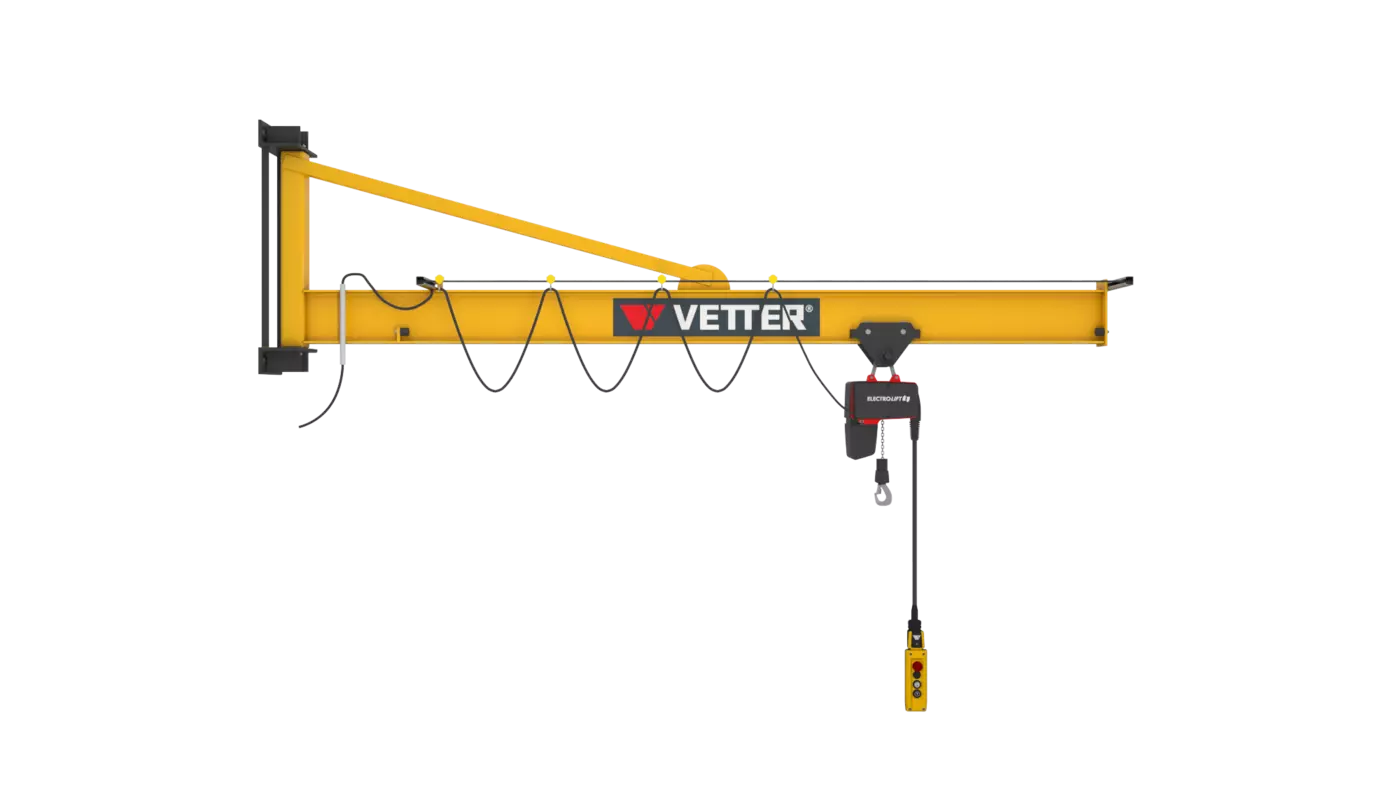

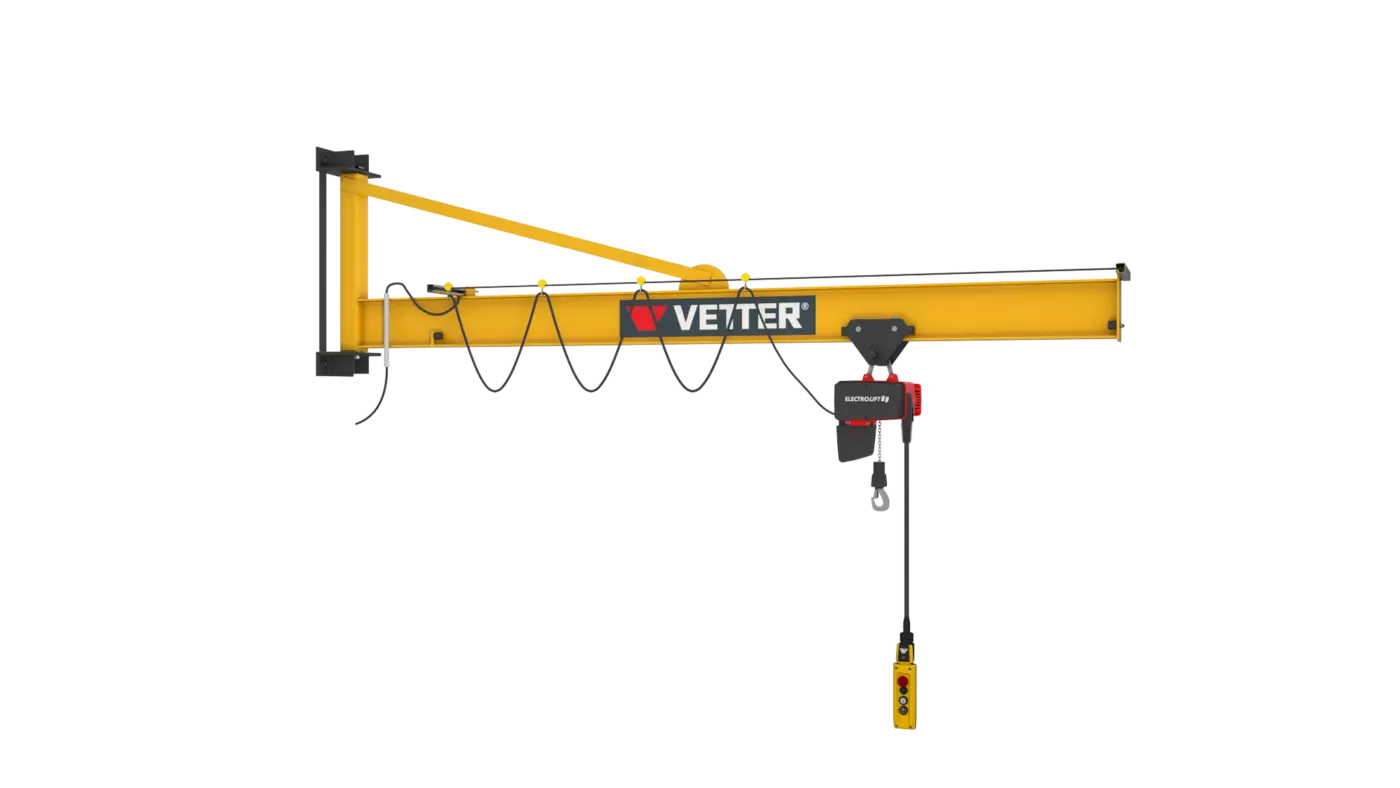

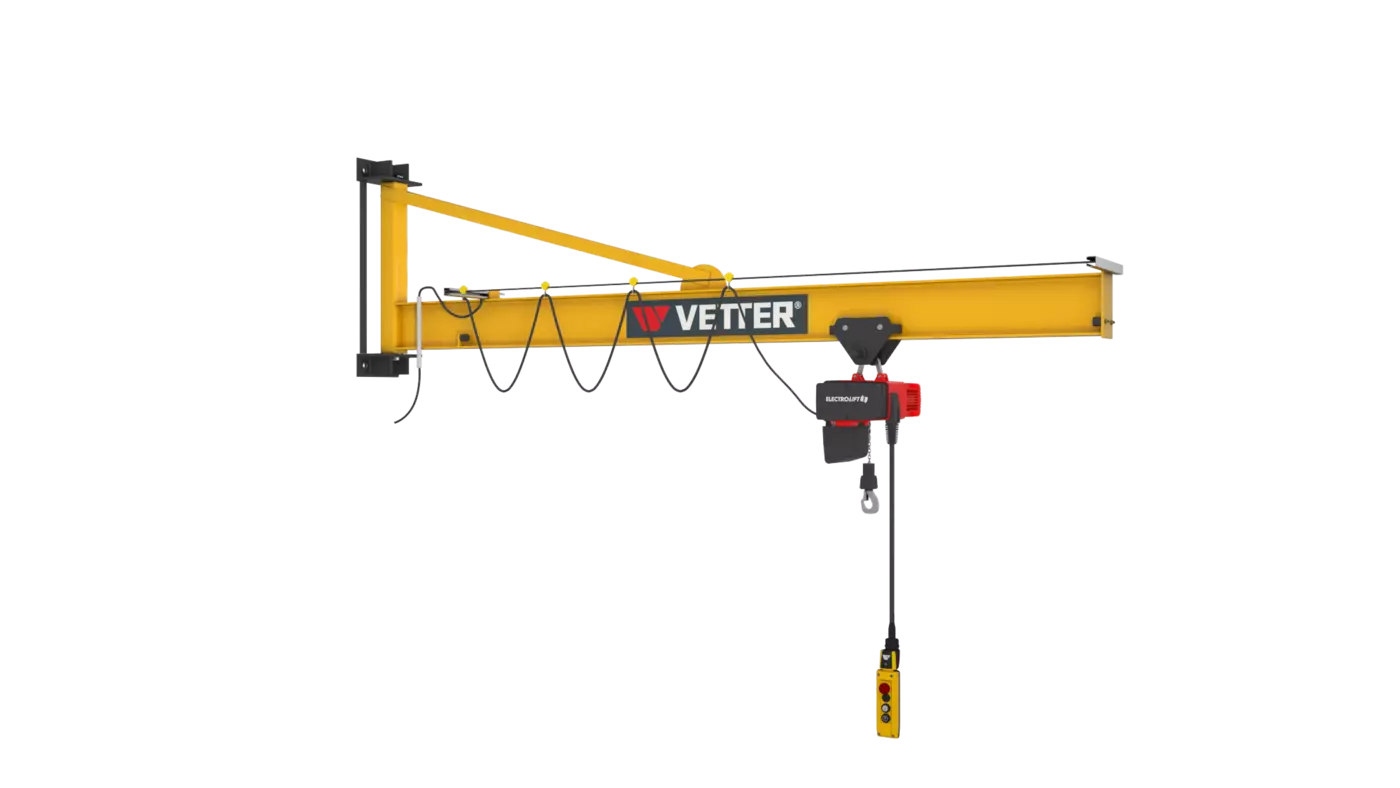

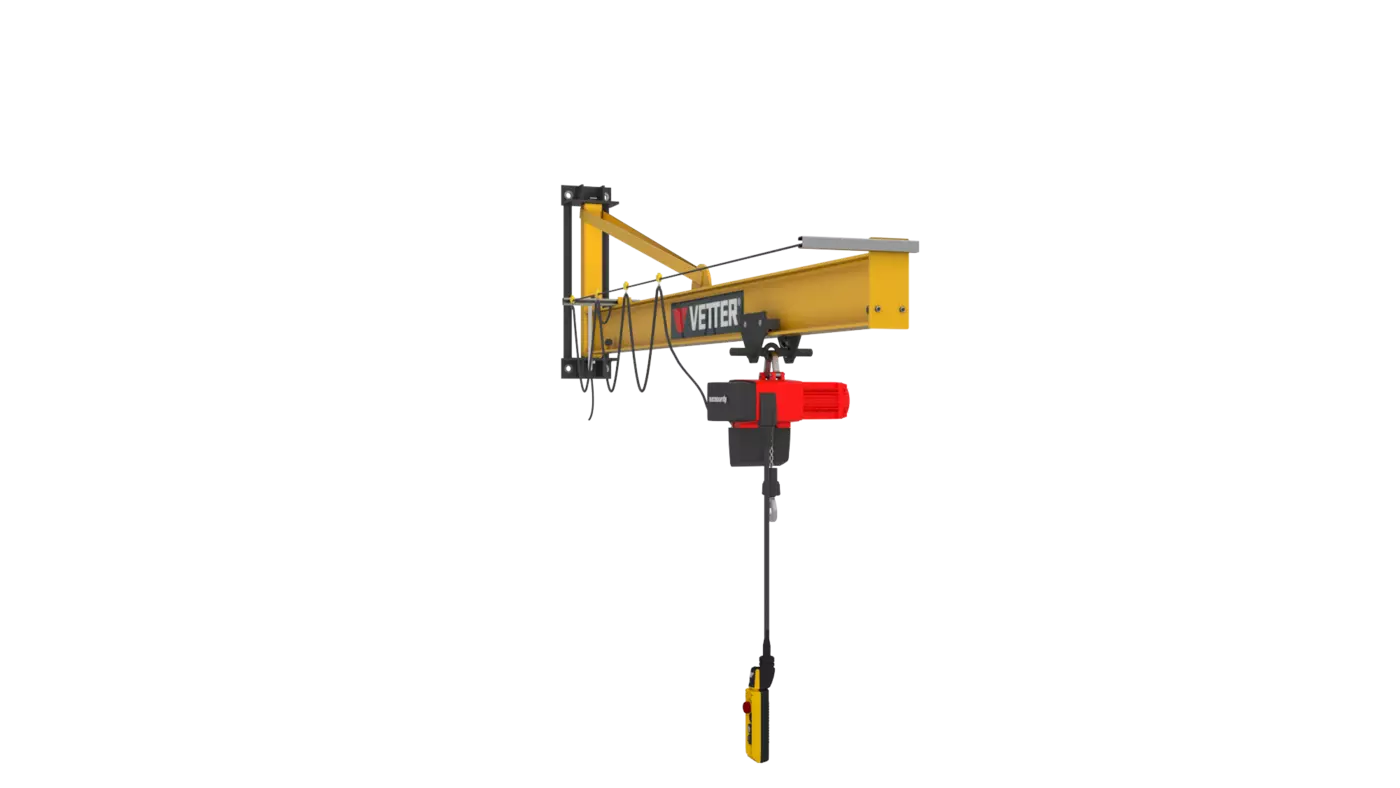

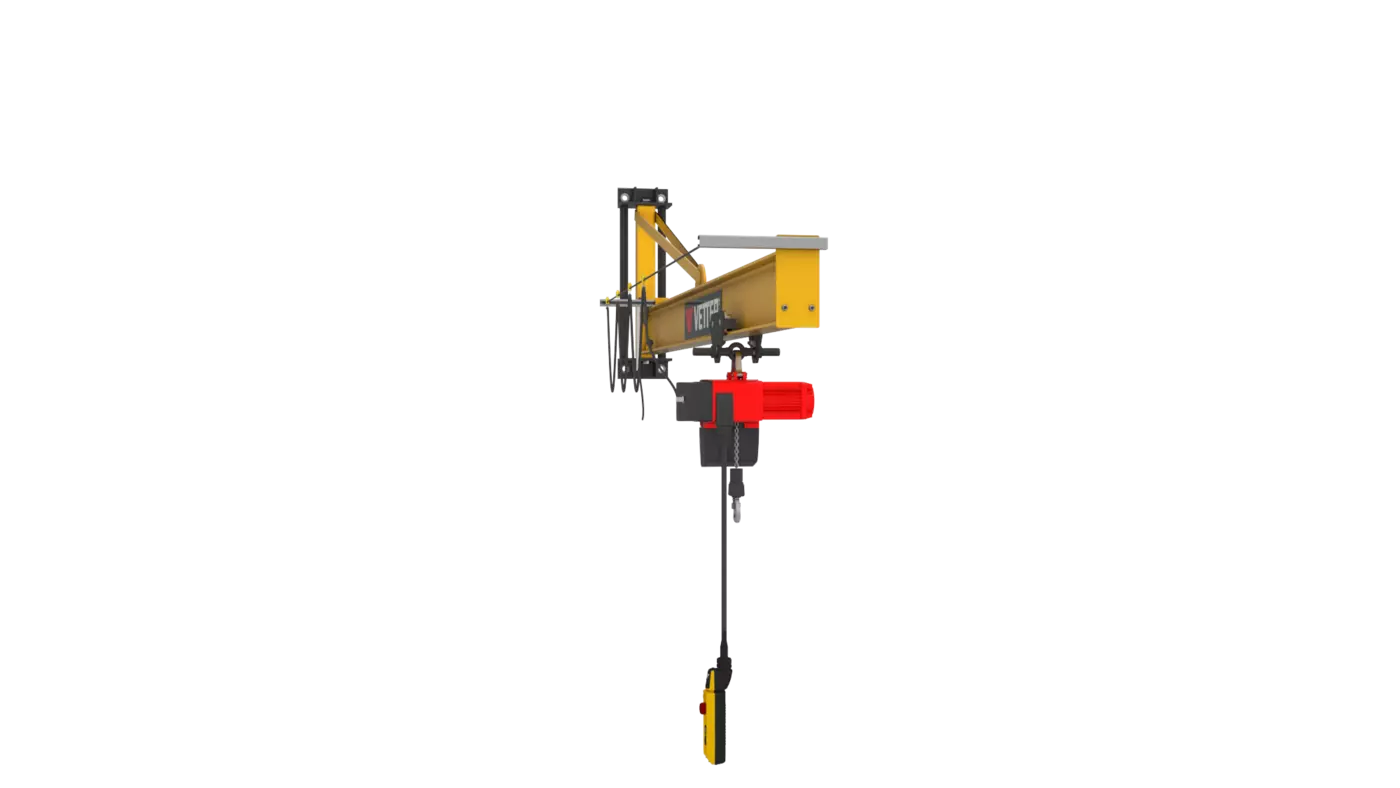

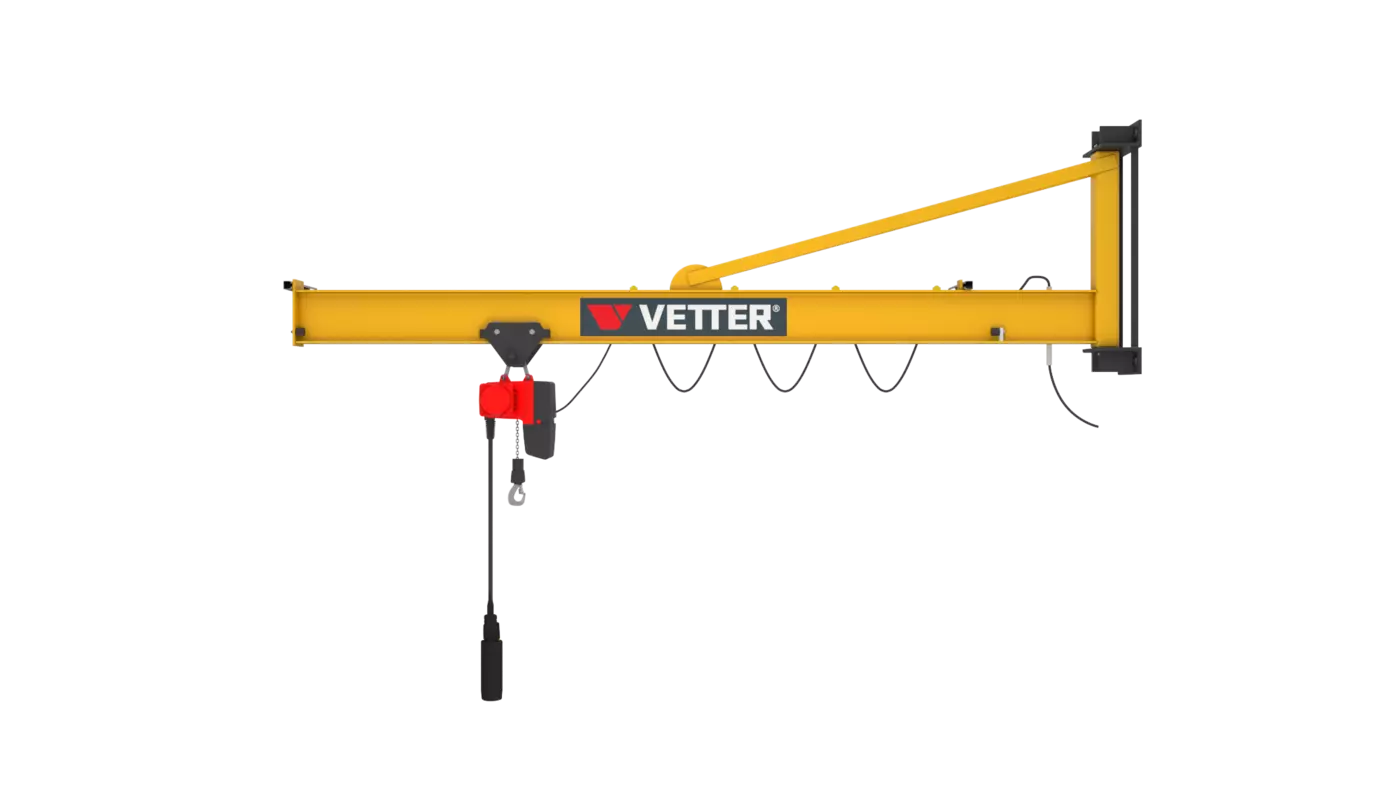

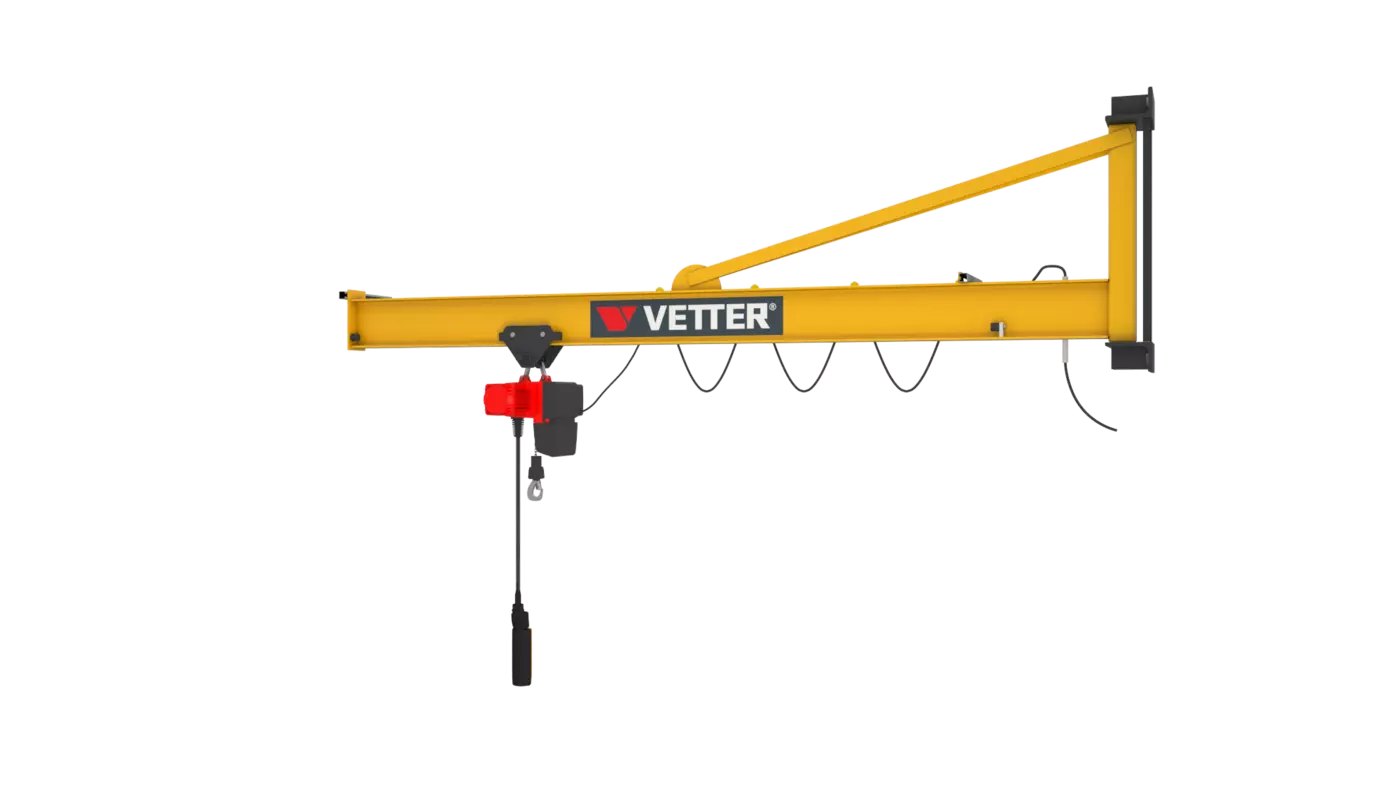

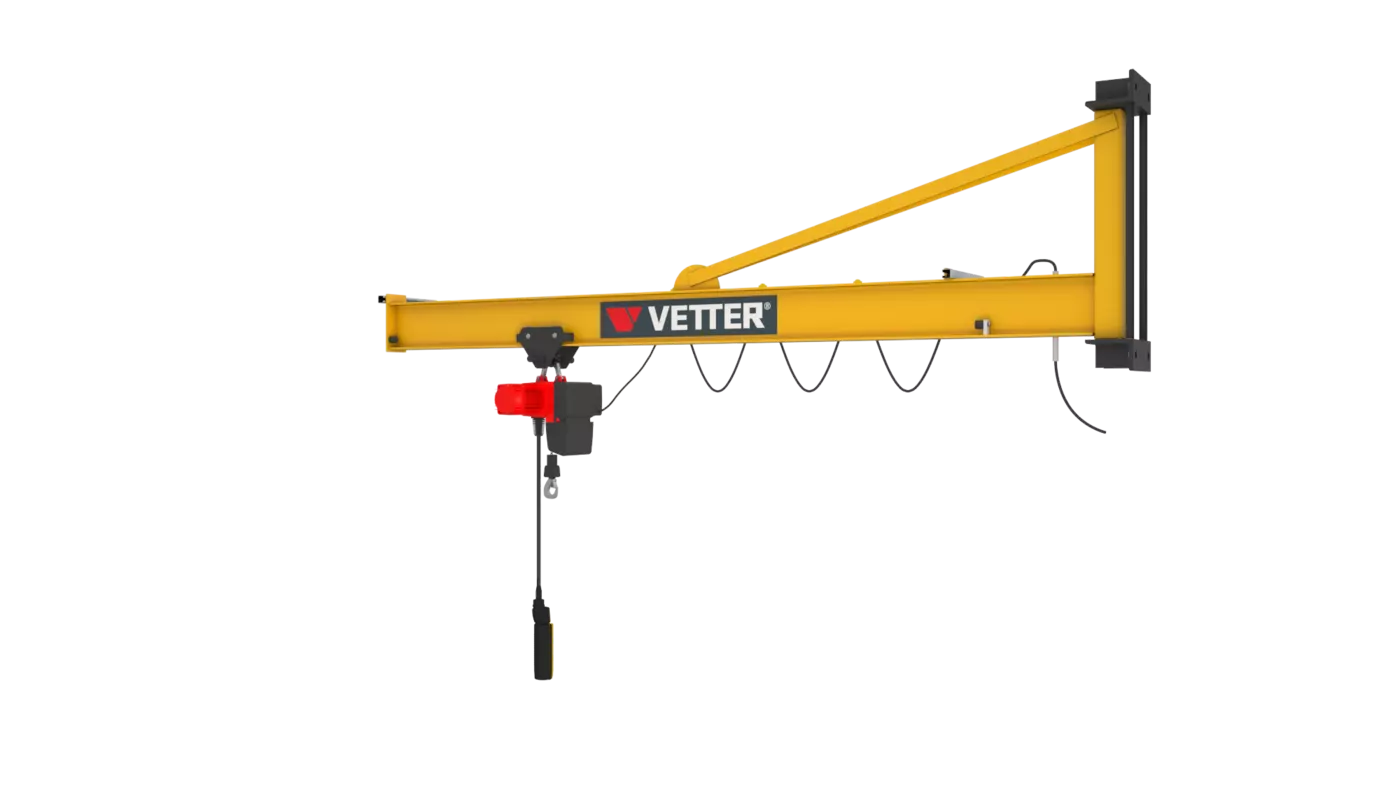

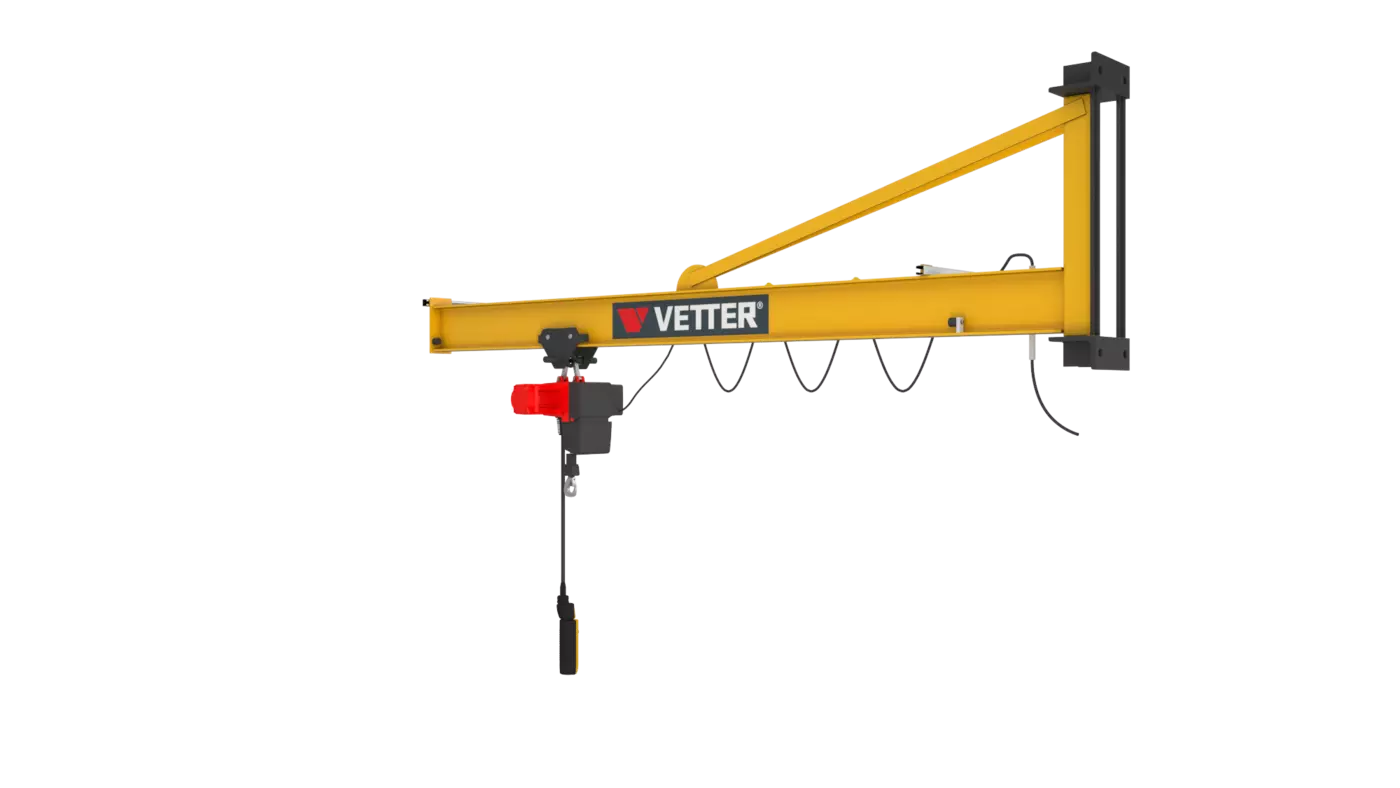

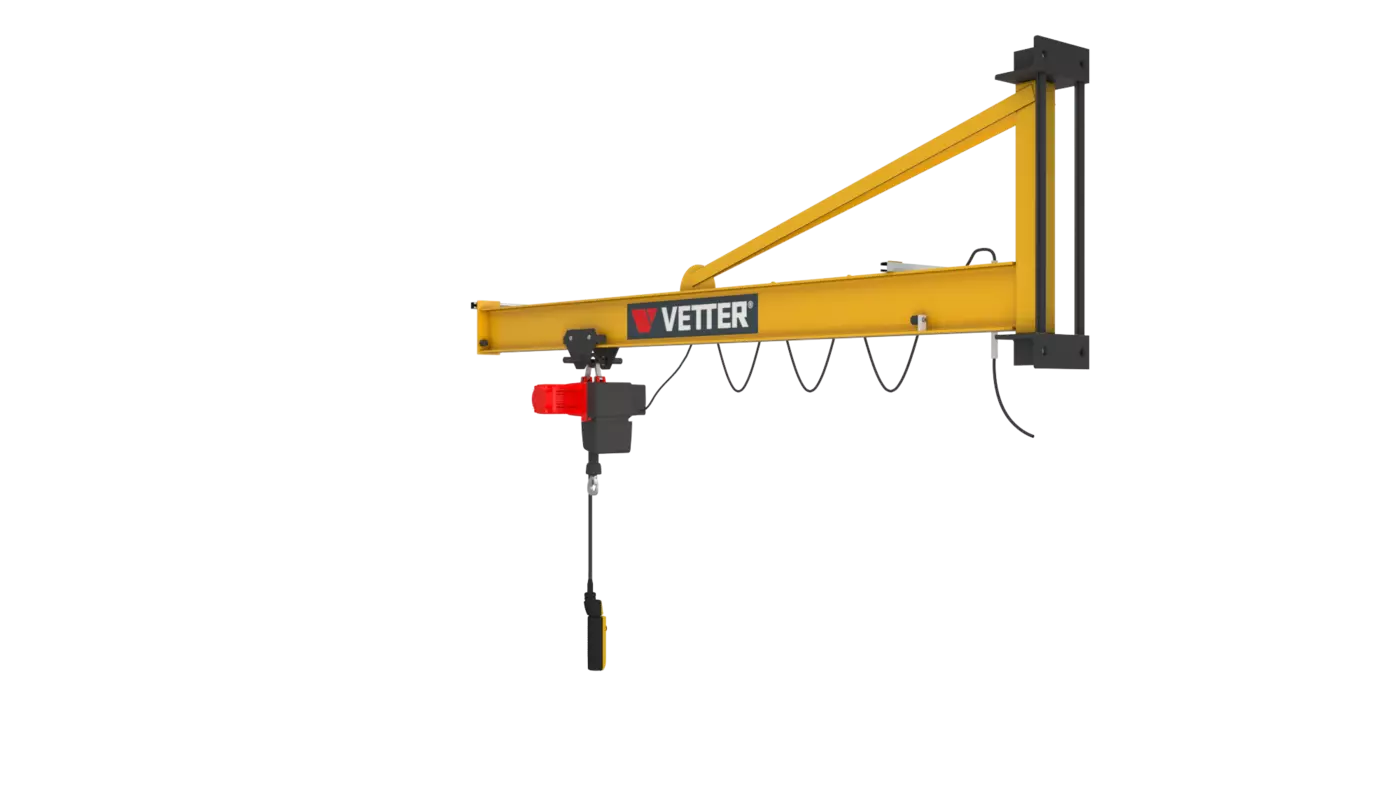

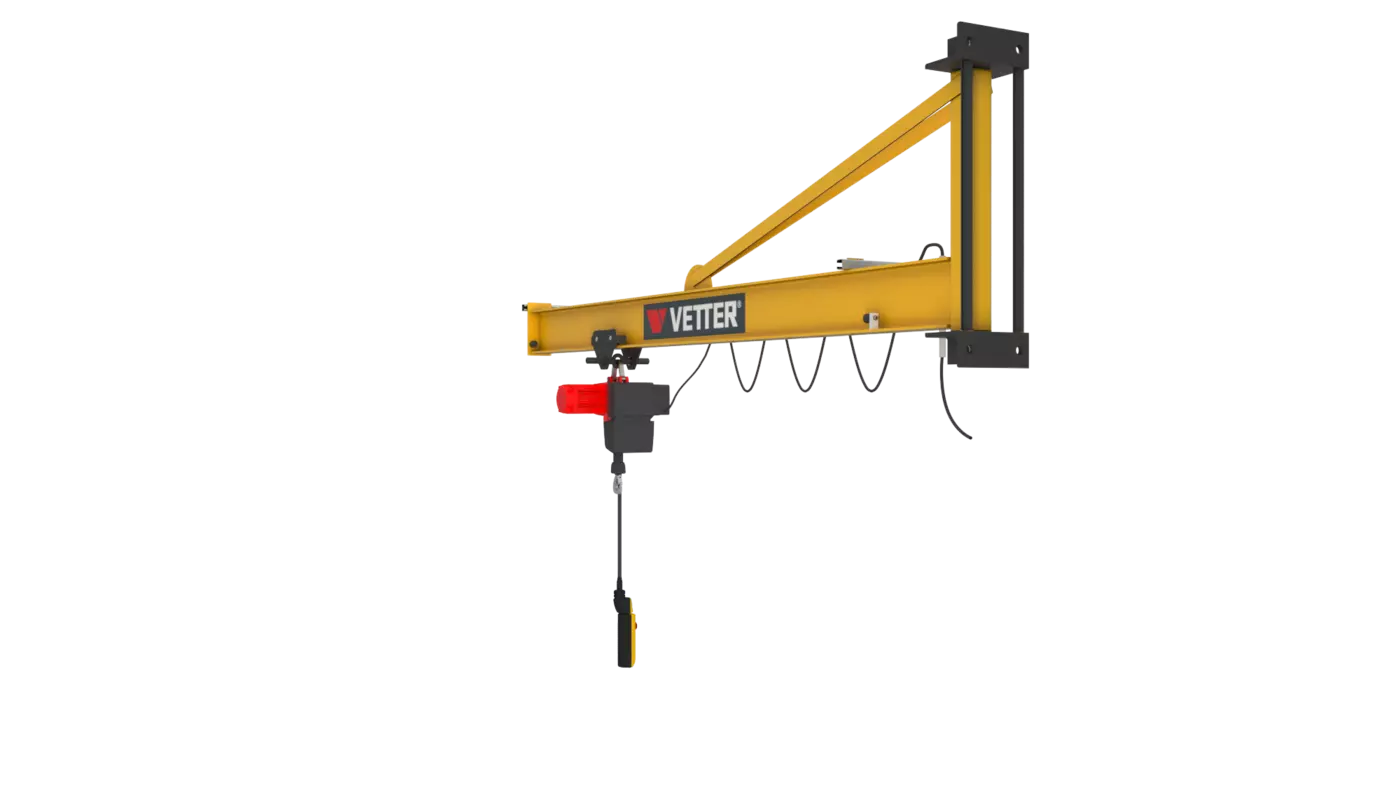

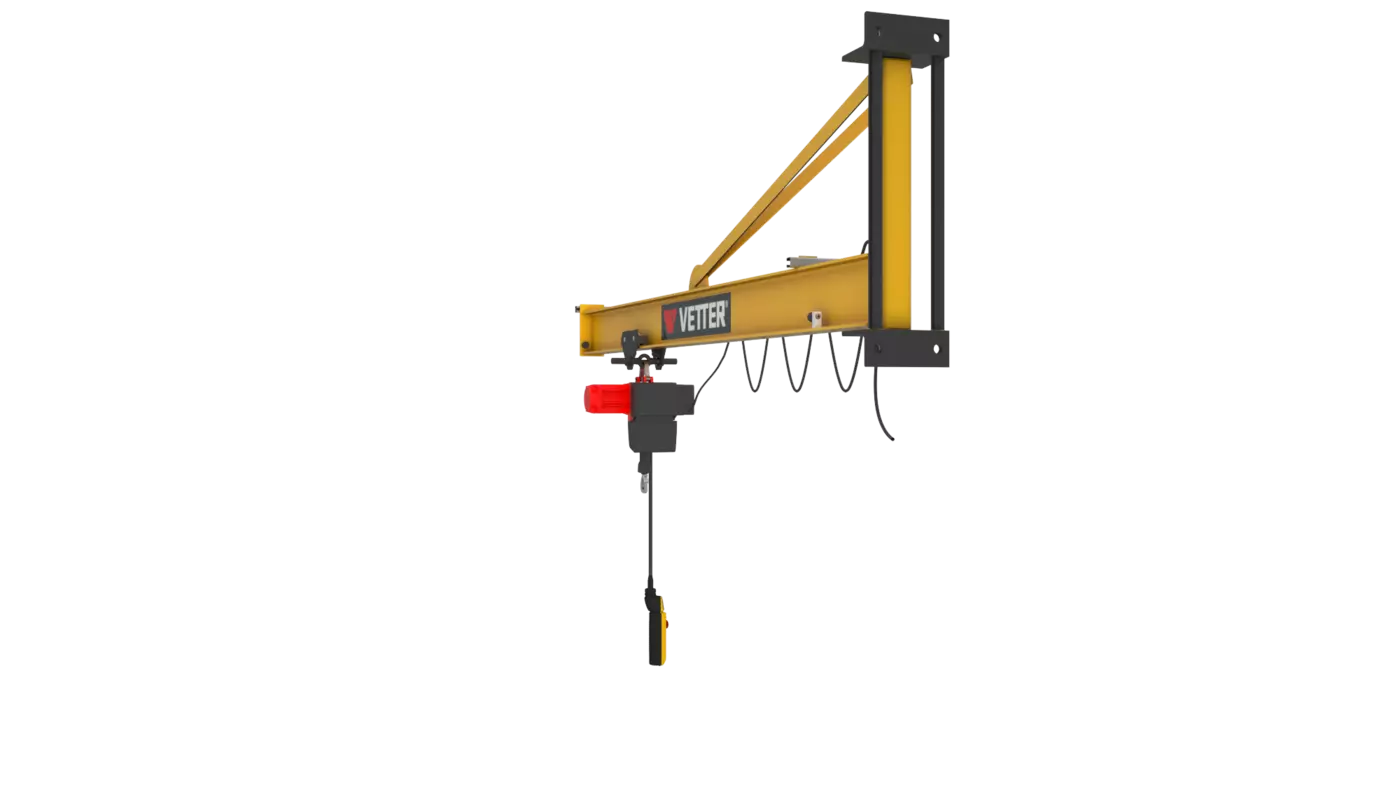

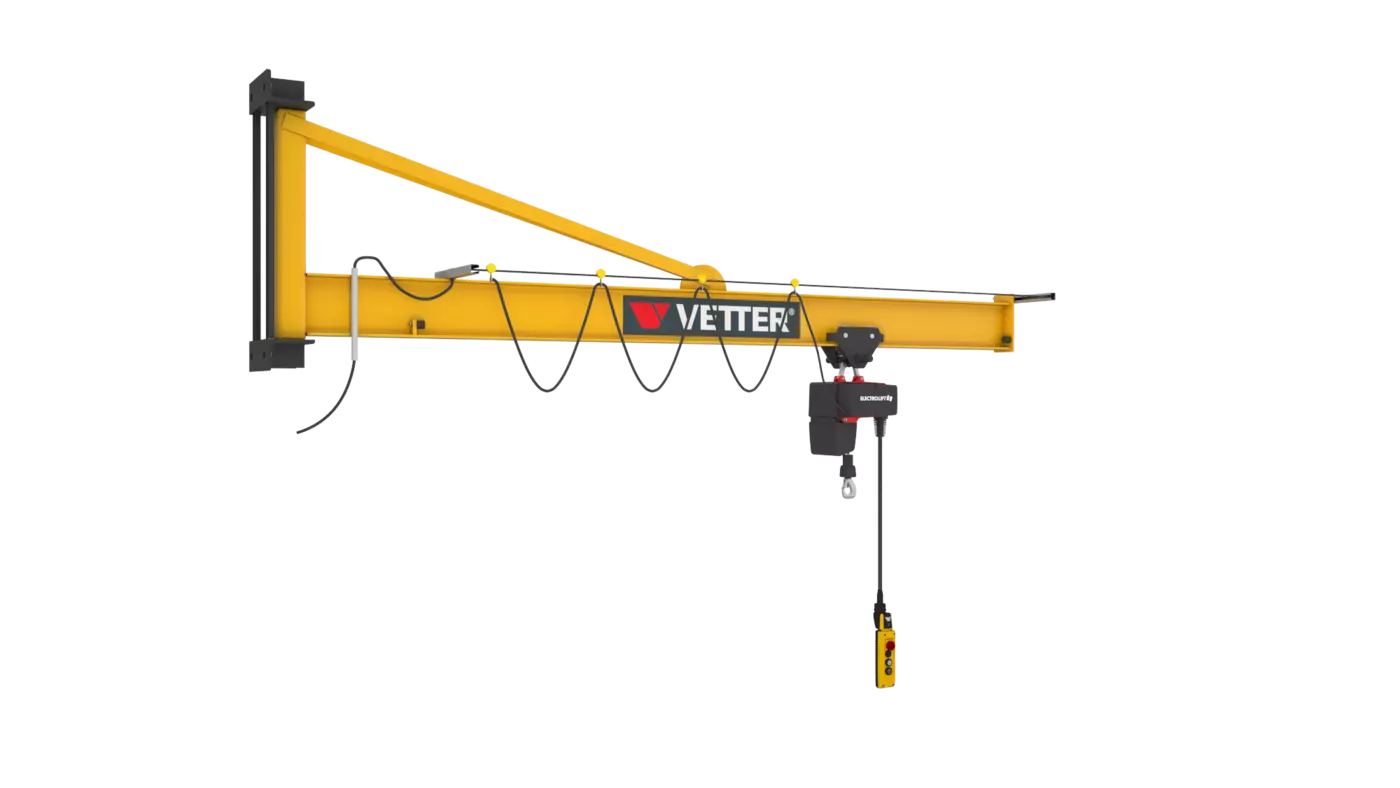

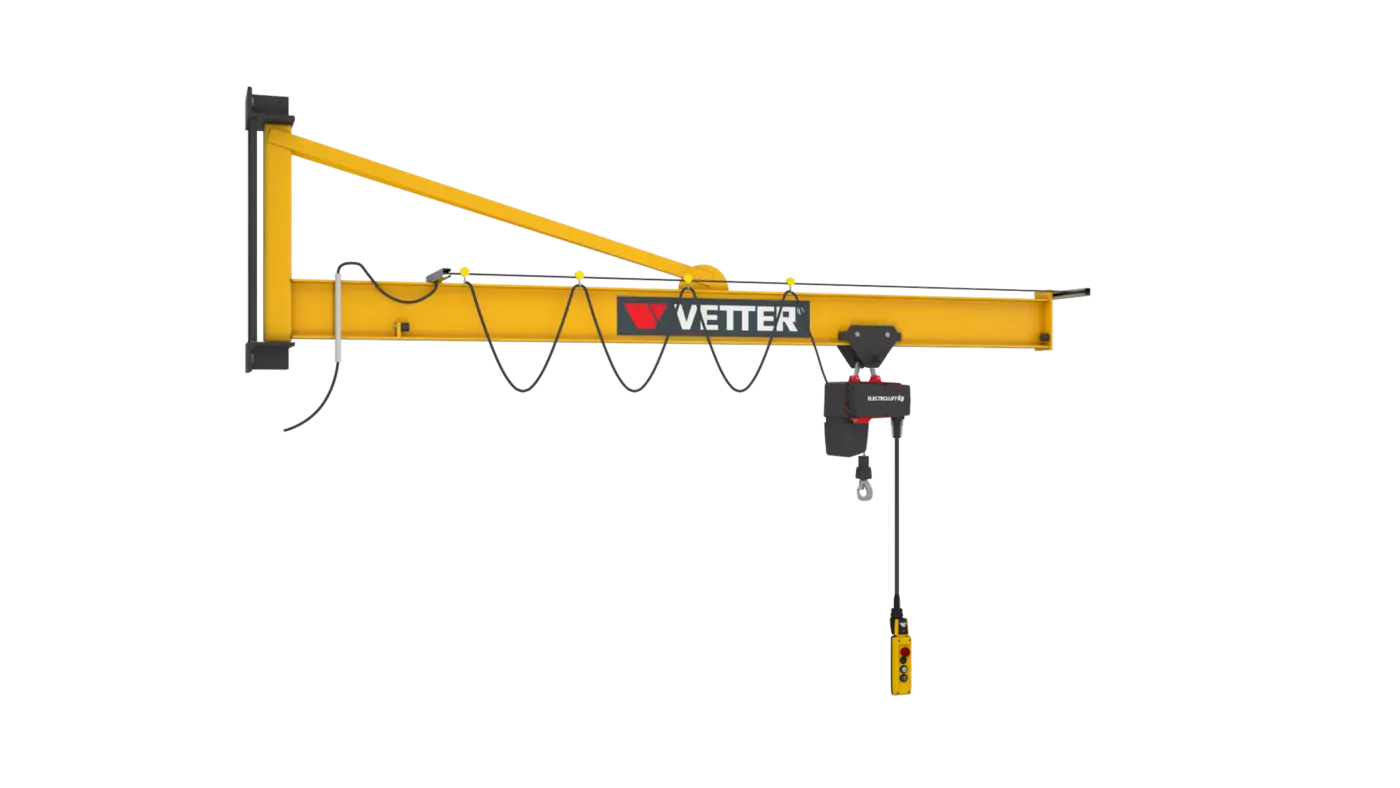

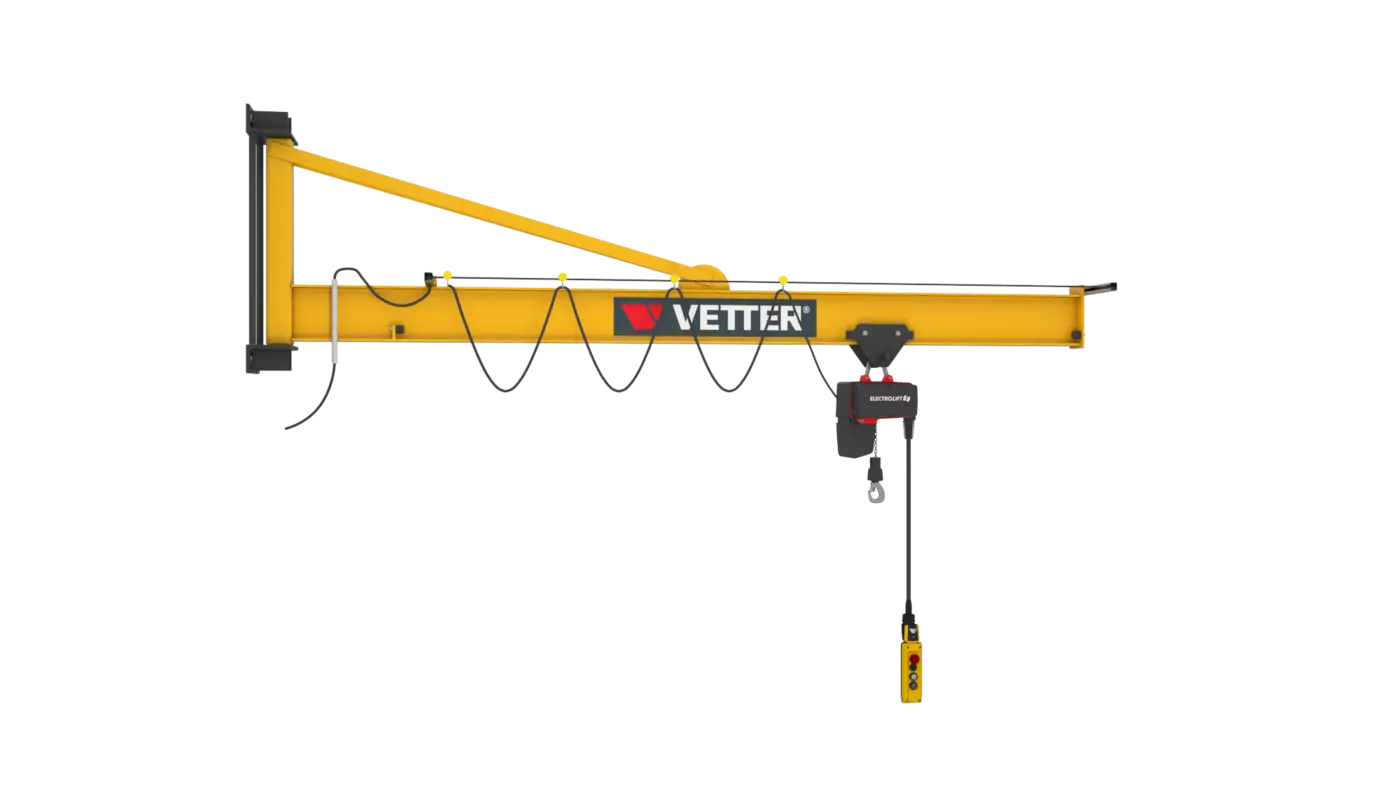

Wall-mounted slewing jib crane

Type PW

Product highlights

- Cost-effective crane

- Easy slewing

- Overbraced design, low dead weight of jib arm

- Outdoor use possible

- Jib arm length can be adjusted to conditions on the spot

- Broad range of fastening options provides for convenient installation

The simple one

The wall-mounted slewing jib crane PW is our cost-effective basic crane!

You can use it for simple operational tasks requiring a capacity of up to 2,000 kg. Its overbraced design and lightweight jib arm enable especially easy slewing of the crane. The wall-mounted slewing crane PW perfectly meets your requirements for indoor and outdoor use since its jib arm length can be adjusted individually.

Regarding fastening options, you can make your individual choice from fastening on steel pillar, reinforced concrete pillar, reinforced concrete wall, and steel structure.

Moreover, we offer a suitable power supply, electric chain host ELECTROLIFT® with electric trolley as well as various other accessories.

This type of slewing crane is also available as column-mounted slewing jib crane.

Technical data

Capacity range

| Capacity: | 80 - 2000 kg |

| Outreach: | 2000 - 6000 mm |

| Total height: | 940 - 1430 mm |

| Slewing range: | 180° |

| EN 13001 Hoisting class: | HC2 |

| EN 13001 Stability class: | S2 |

| Jib design: | Overbraced |

| Slewing: | By hand |

| Hoist: | Chain hoist |

| Trolley drive: | By hand / Electrical |

| Installation location: | Indoor / Outdoor |

Outreach [m]

Capacity [kg]

| 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | |

|---|---|---|---|---|---|---|---|---|---|

| 80 | |||||||||

| 125 | |||||||||

| 250 | |||||||||

| 500 | |||||||||

| 800 | |||||||||

| 1000 | |||||||||

| 1600 | |||||||||

| 2000 |

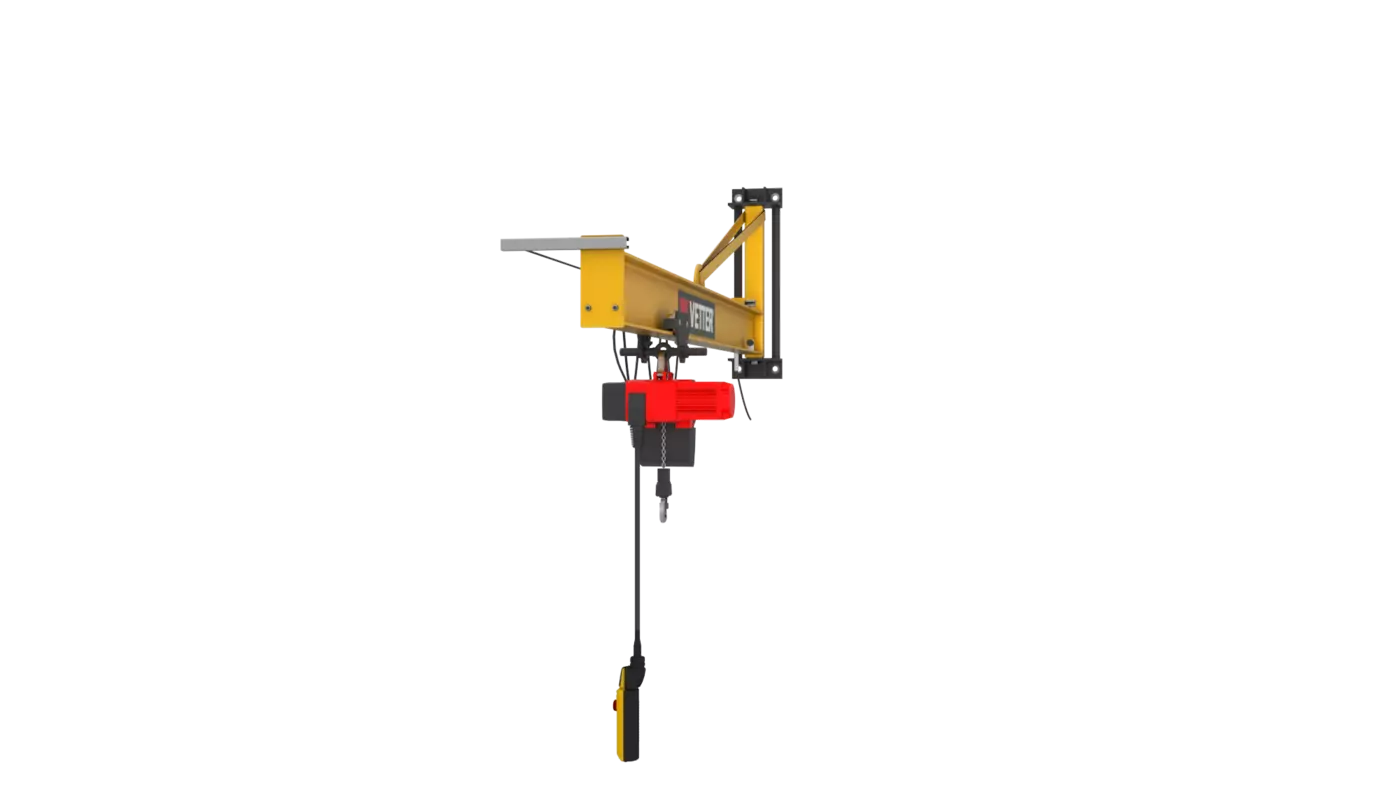

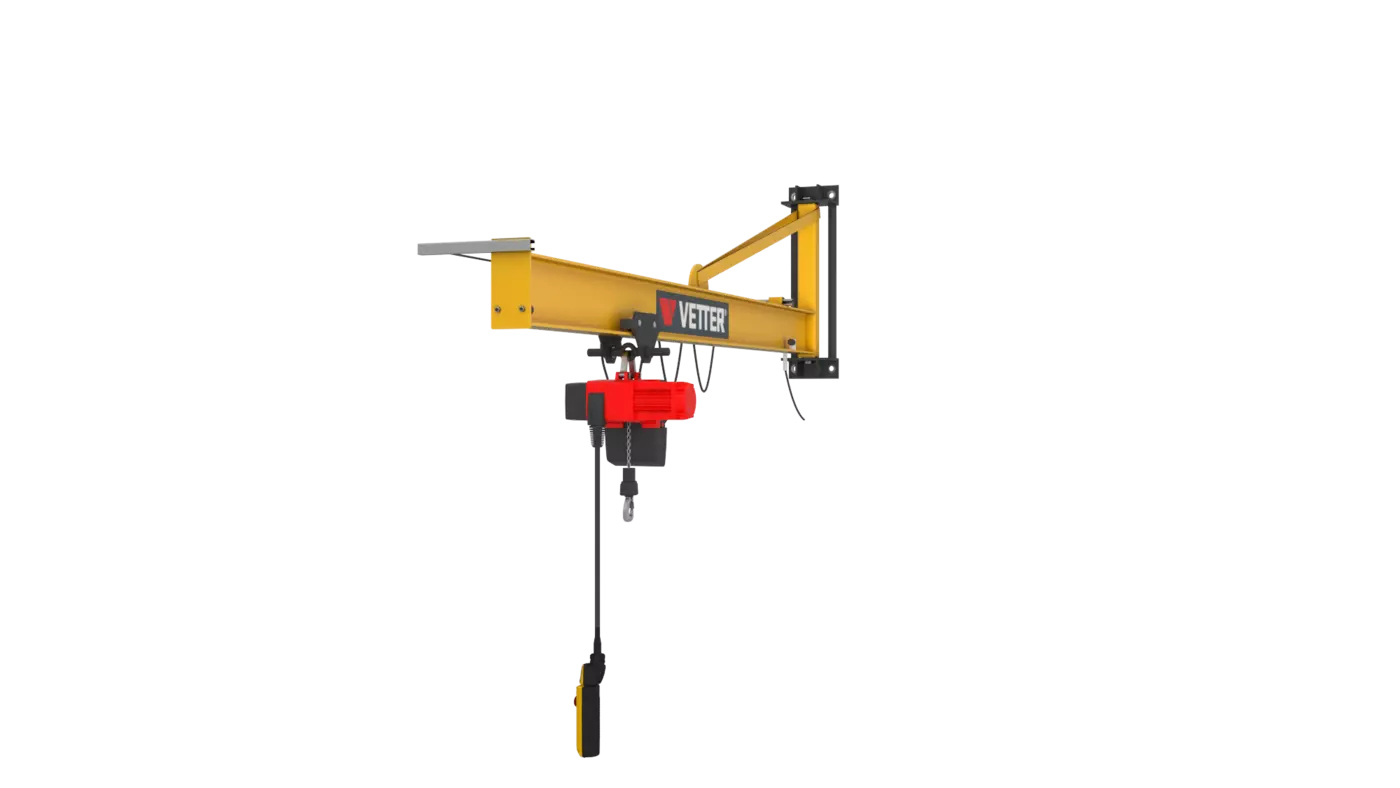

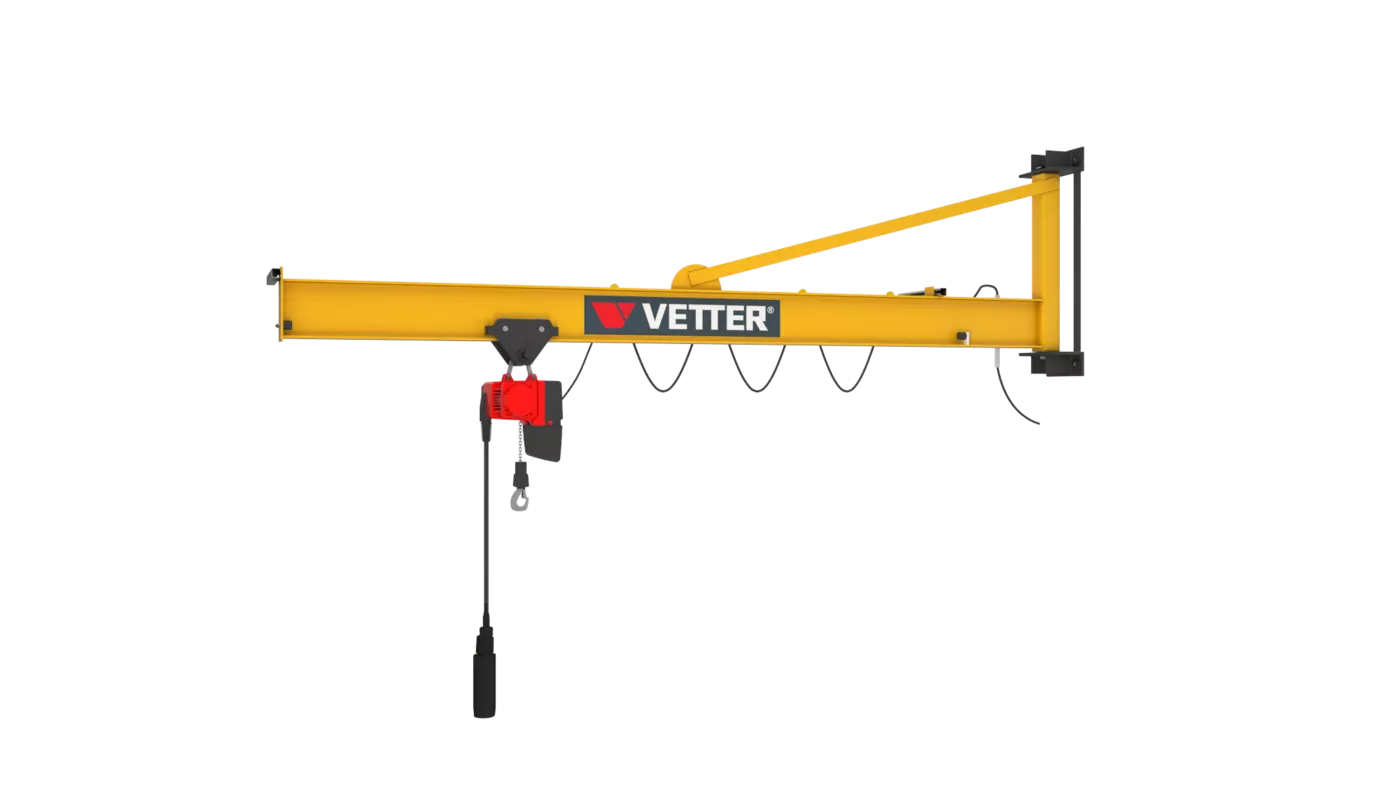

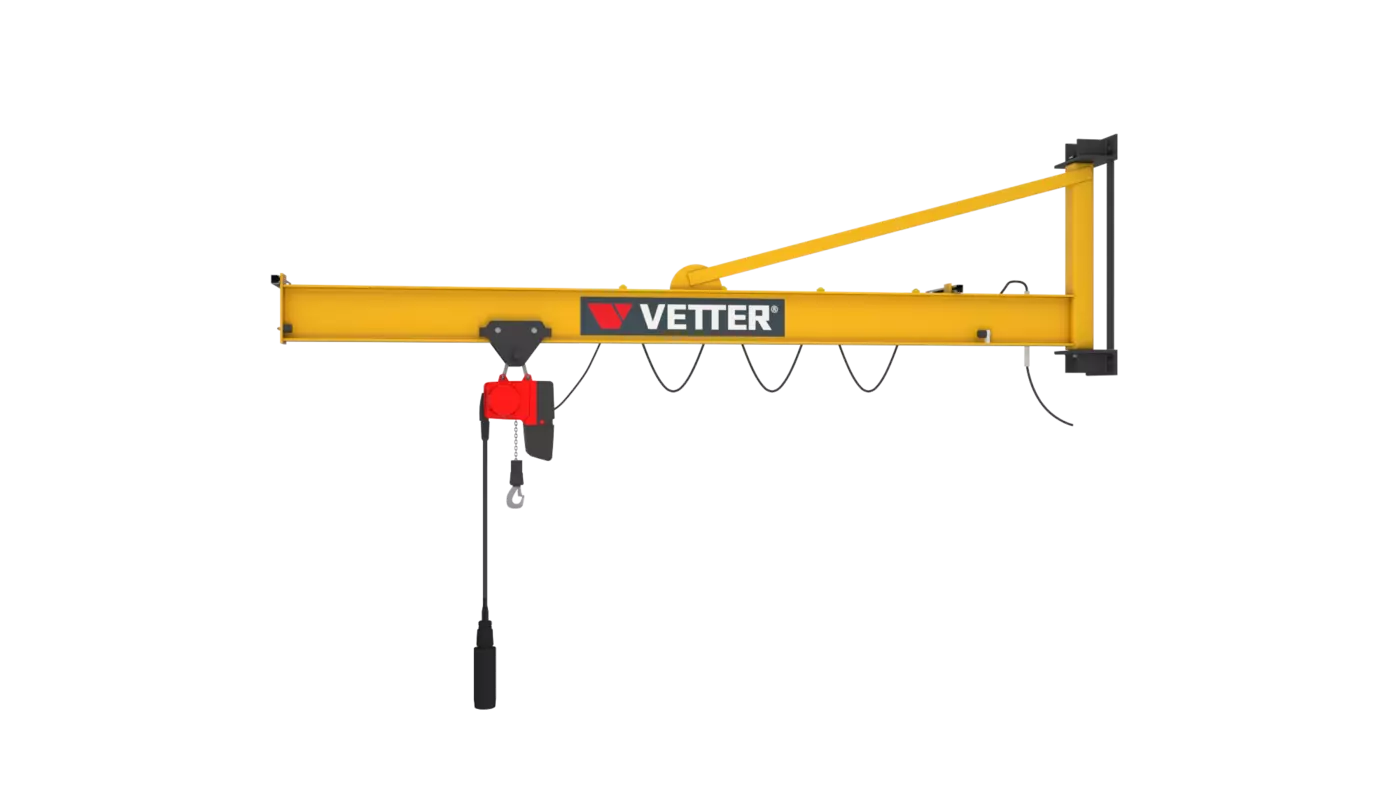

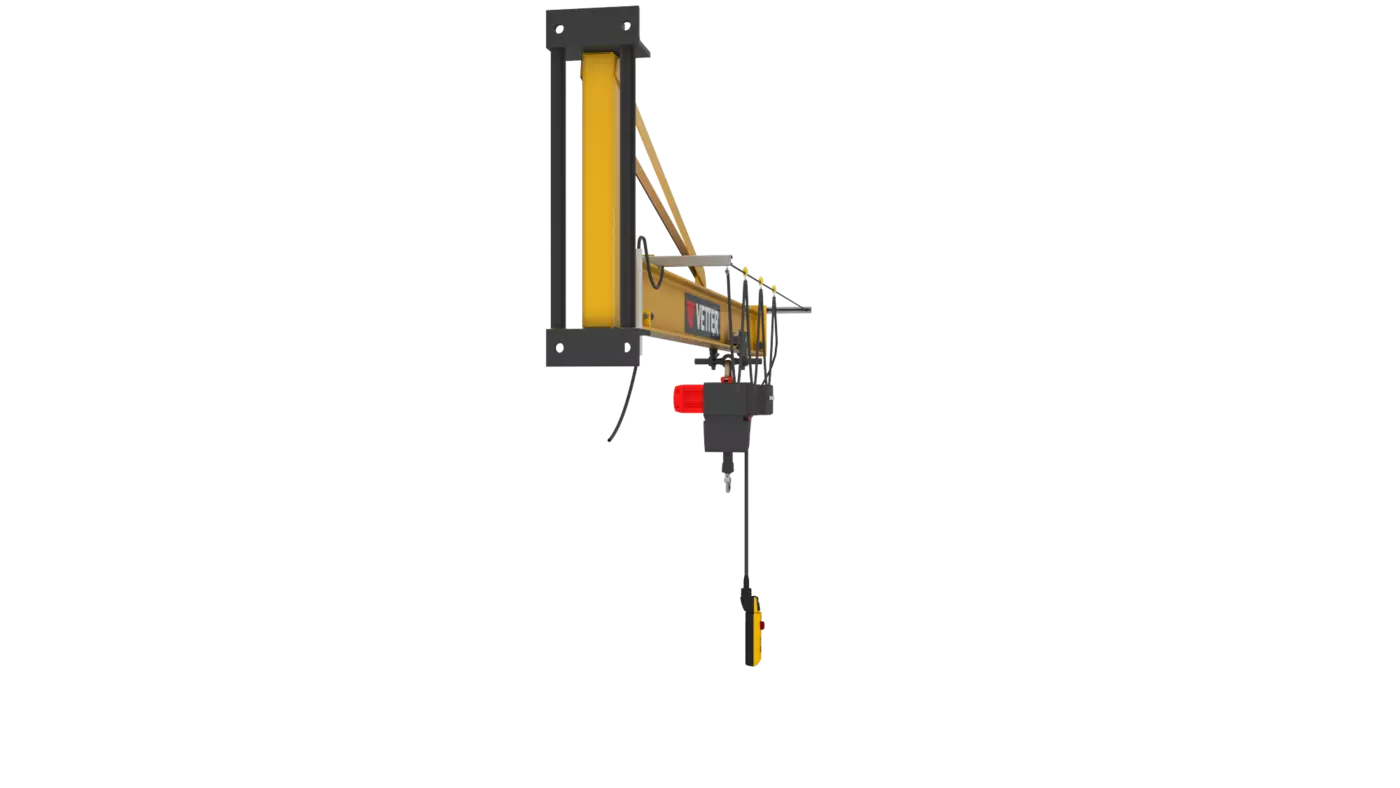

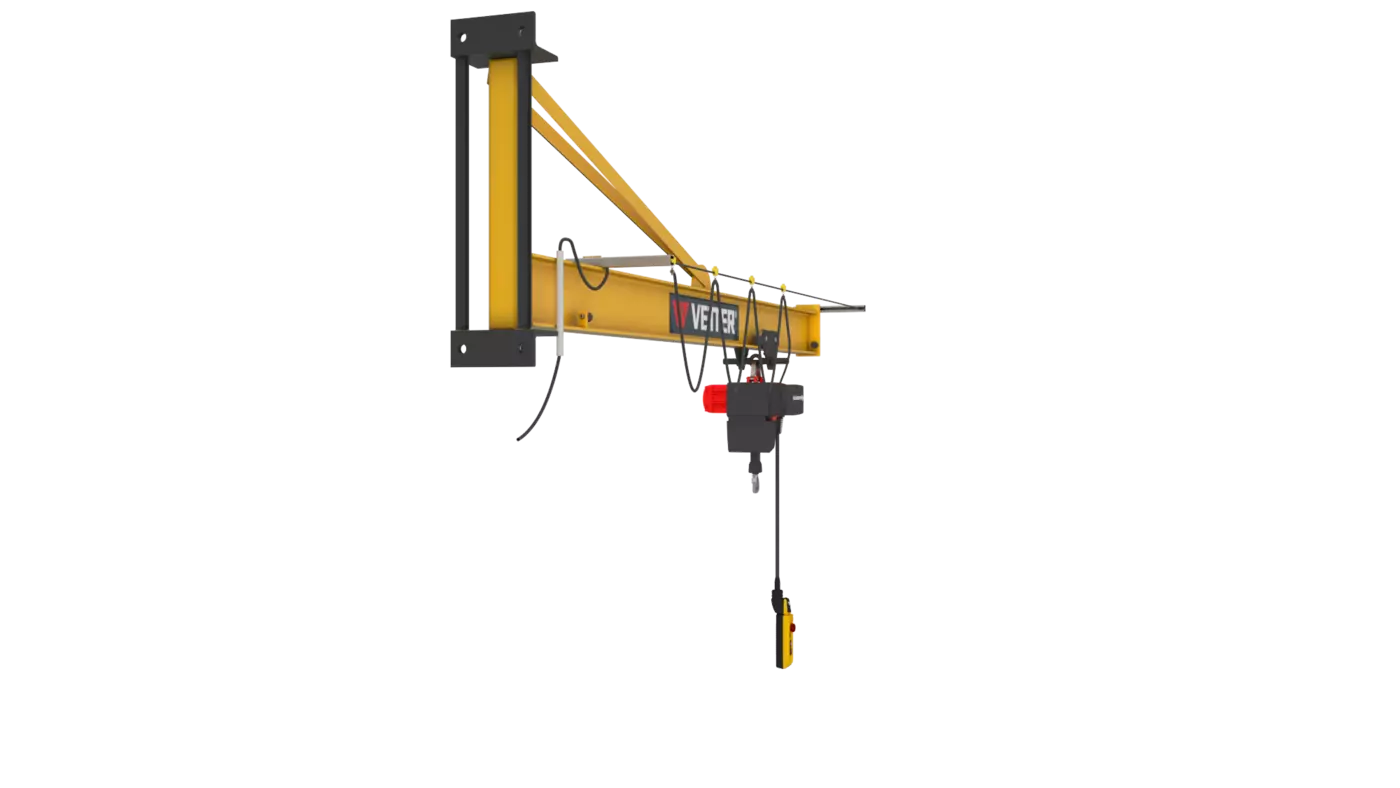

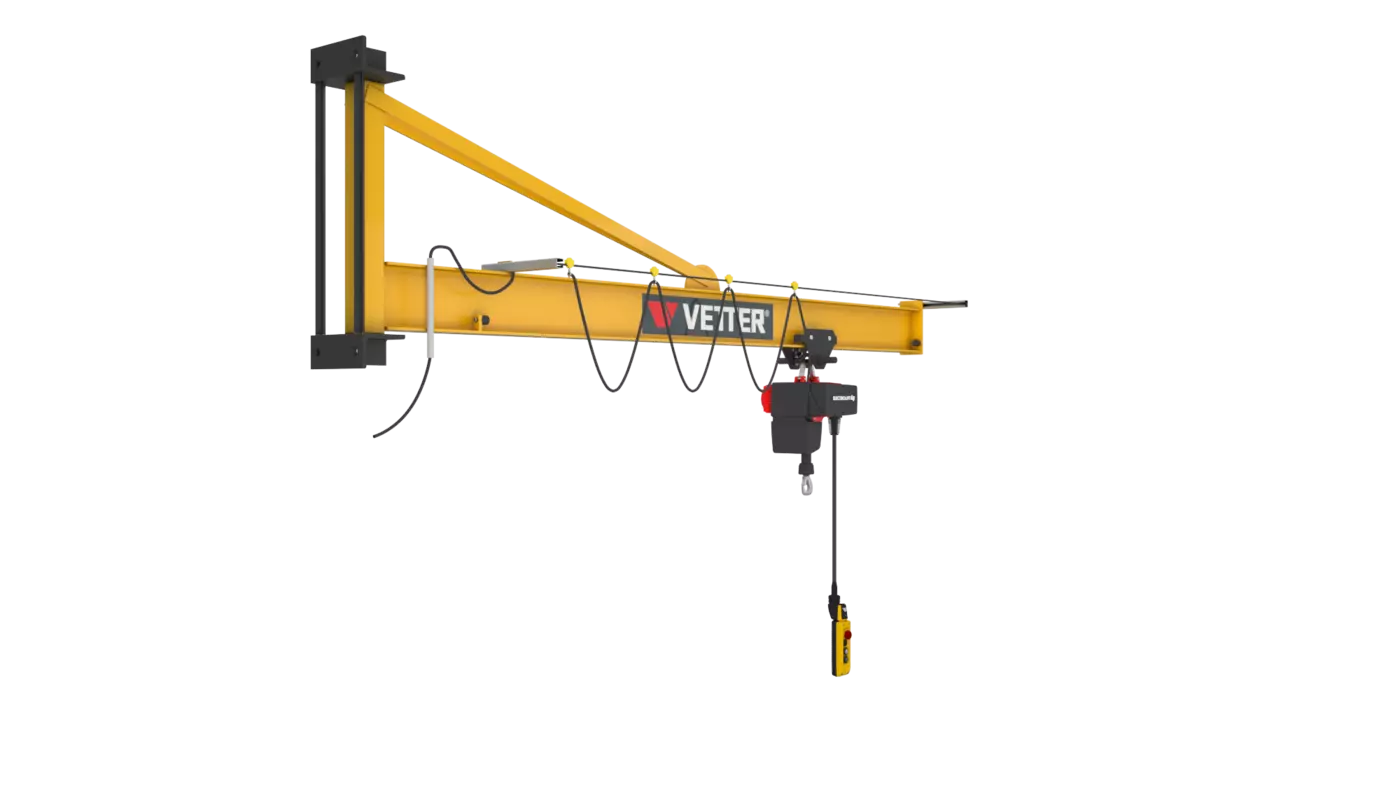

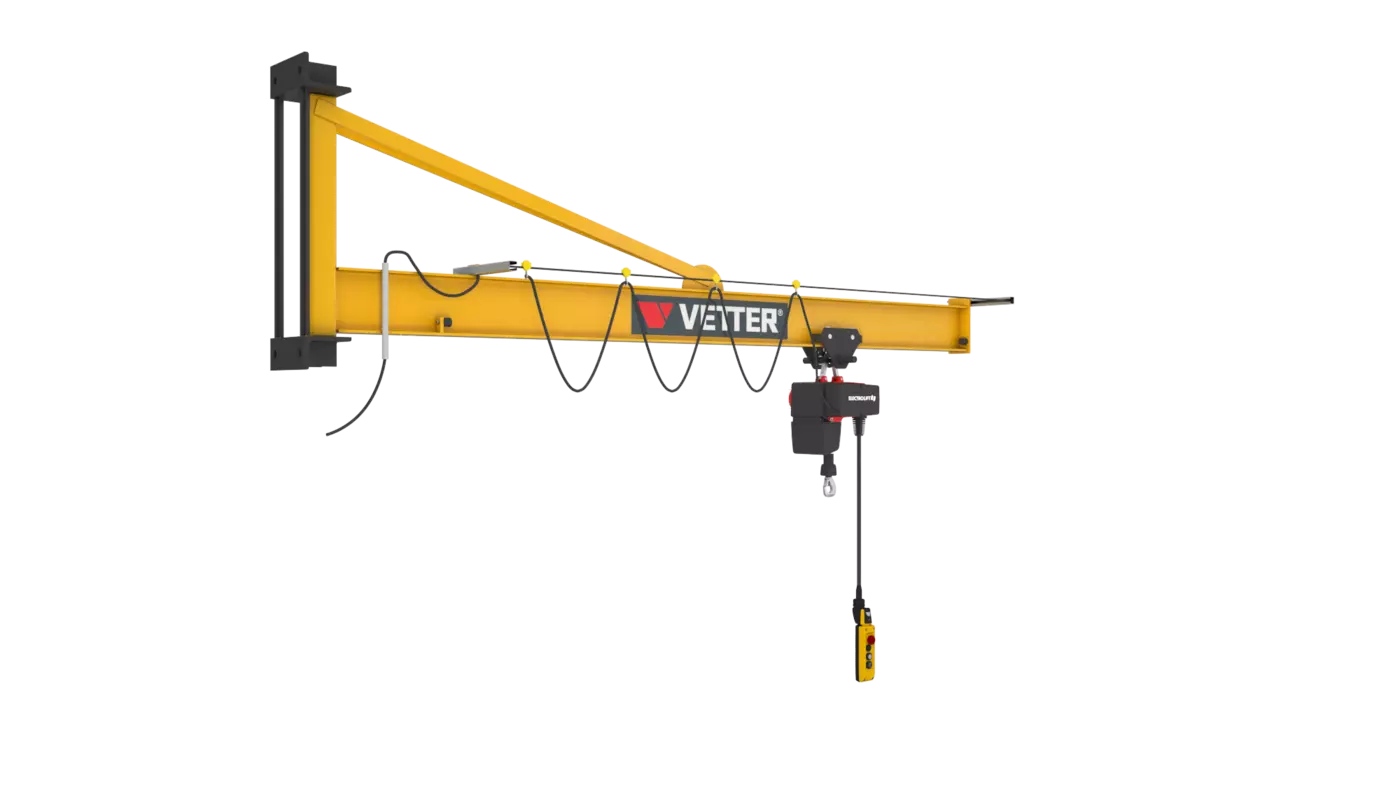

3D view

Accessories

Fastening

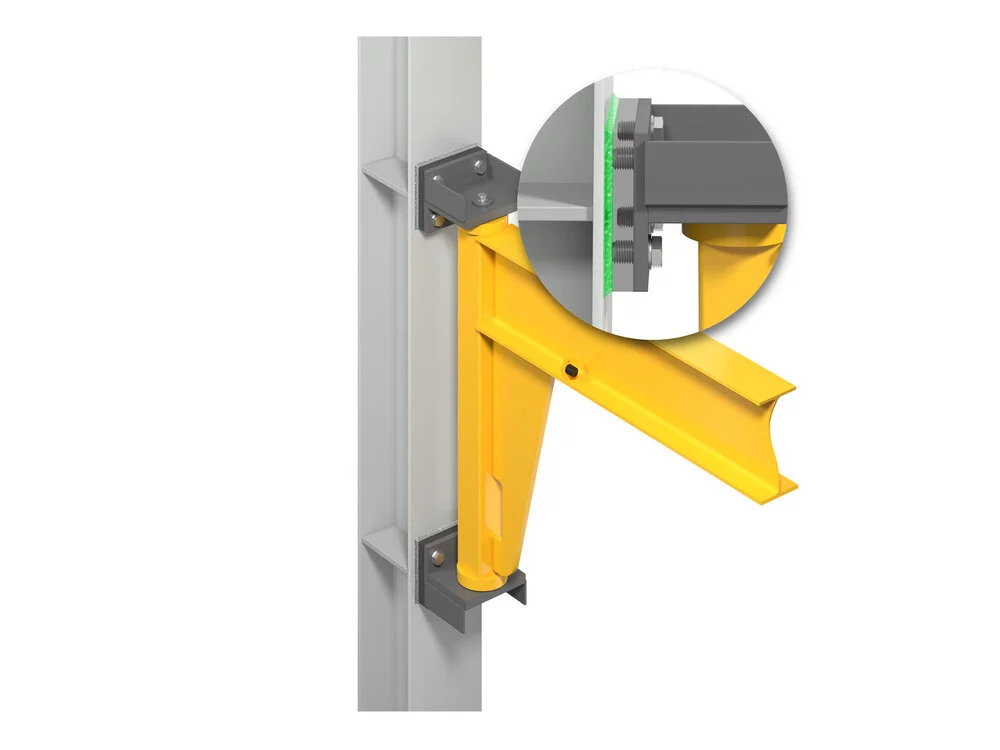

Fixing on steel pillars

Bearing bracket

The screwable bearing bracket is used to attach jib cranes directly to steel pillars. This fastening is standard delivery scope.

Fixing on concrete walls

Wall bracket

For fastening jib cranes on concrete walls. The bracket plate is mounted on the wall by the included threaded rods, nuts an washers.

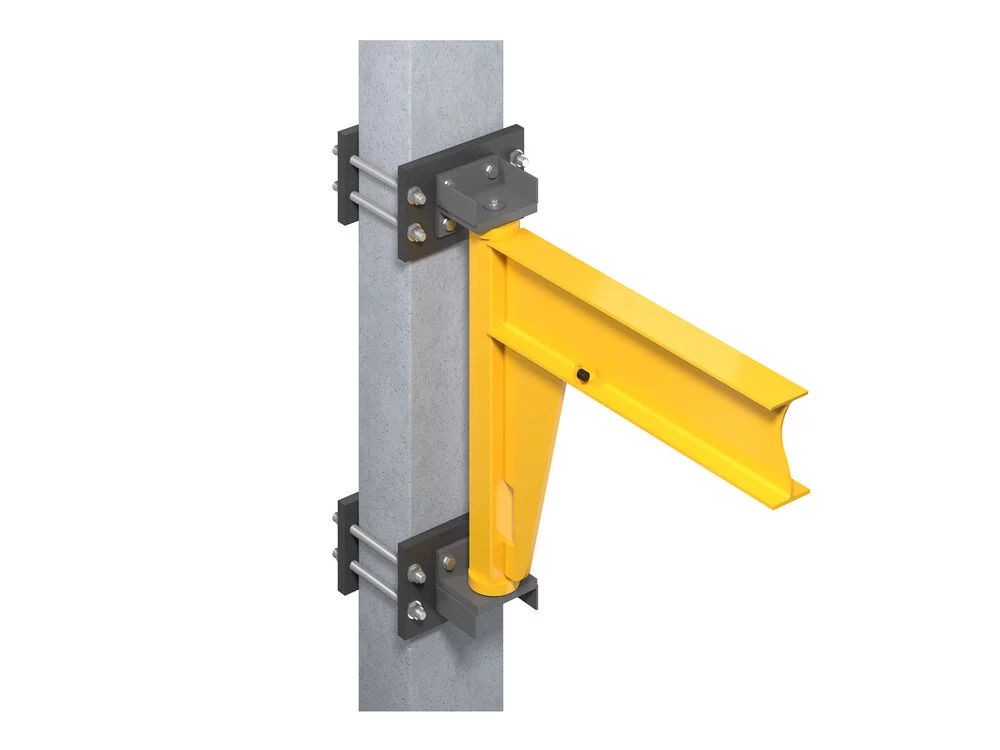

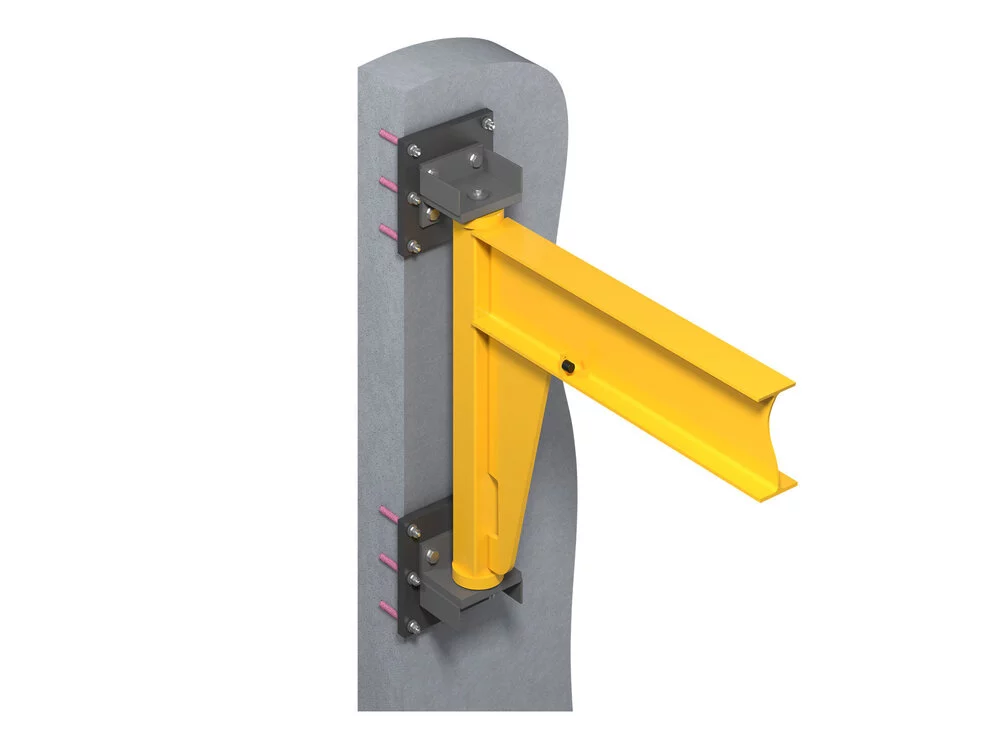

Fixing on reinforced concrete pillars

Support embarcing bracket

For fastening jib cranes on reinforced concrete pillars. The front bracket plate is clamped to the pillar by the included threaded rods, nuts and counterplate.

Fastening to steel structure

Weld-on bracket

Designed to attach the wall-mounted slewing jib crane to a steel structure which is suitable regarding static strength. The bracket is welded directly onto the steel structure. This fastening option is perfectly suited if is not possible or allowed to drill holes into the existing steel structure.

Dowel fixing to concrete wall

DowelPlate system

The complete solution for doweling the wall-mounted slewing jib crane to an existing, load-bearing concrete wall with the VETTER DowelPlate system.

Power lead

Round cable

Power lead by cable loop, consisting of round cable and cable supporting tube to be mounted on the jib arm. Pendant control fixed to the hoist. Suitable for an outreach up to 3-5m (Depends on the jib clearance of the jib arm).

Round cable trailing system

Favourable power supply, consisting of round cable, cable trolleys, tensioning rope and suspension arms to fix the supply to the jib arm. Pendant control fixed to the hoist. Recommended for outreachs from 3-10 m (Depends on the jib clearance of the jib arm).

Other

Slewing limitation

Mechanical slewing limitation, can be installed and adjusted easily and continuously.

Locking device

For locking the jib arm in several positions. Applied by lever arm / traction rope (depending on crane

type) with control lever. Also to be used as immobilizer system up to wind force 7 Beaufort (only when crane is switched off and hoist is in idle position).

Outdoor use

Weatherproof design for temperatures ranging from -20° C to +40° C, wind force up to 4 Bft (moderate breeze), protection class IP55, and insulation class F.

Outdoor design includes sealed bearings, neoprene cables, weather protection roofs for hoist and slewing gear as well as a high-quality outdoor varnish on the basis of corrosion category C3. A hot-dip galvanised steel structure is recommended for outdoor use.

Surface finish

Paint system for indoor use

Cranes intended to be used in a hall are steel grit blasted and provided with a high-quality coating on the basis of corrosion category C2. It is suitable for minor atmospheric stress. The standard colour is daffodil yellow (RAL 1007) with a nominal layer thickness of 80 µm.

Other RAL shades, corrosion categories, and layer thicknesses are available as an option.

Paint system for outdoor use or production halls with high humidity

Cranes intended to be used outside require a special outdoor paint. For this purpose, the crane structure is steel grit blasted and provided with a high-quality outdoor coating on the basis of corrosion category C3. It is suitable for medium atmospheric stress. The standard colour is daffodil yellow (RAL 1007) with a nominal layer thickness of 120 µm.

Other RAL shades, corrosion categories, and layer thicknesses are available as an option.