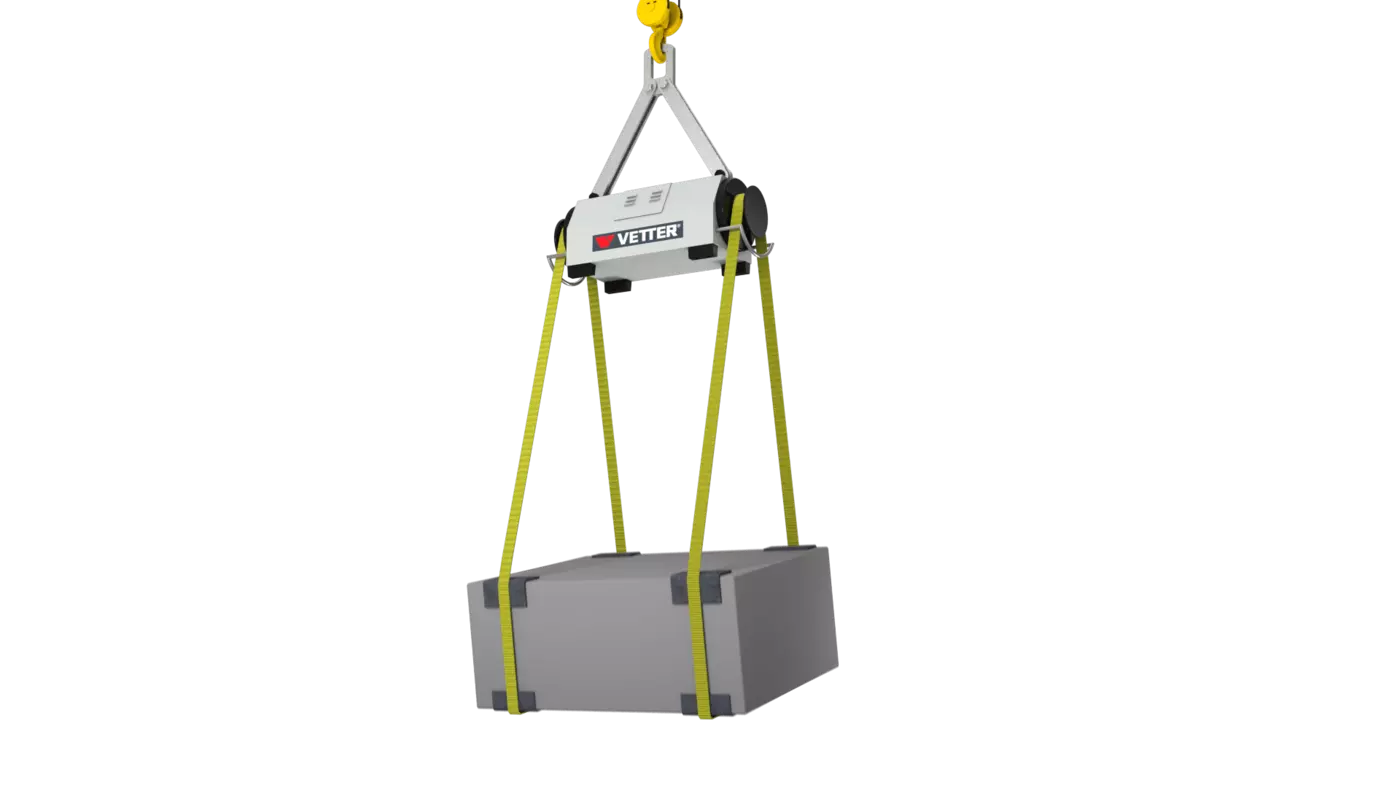

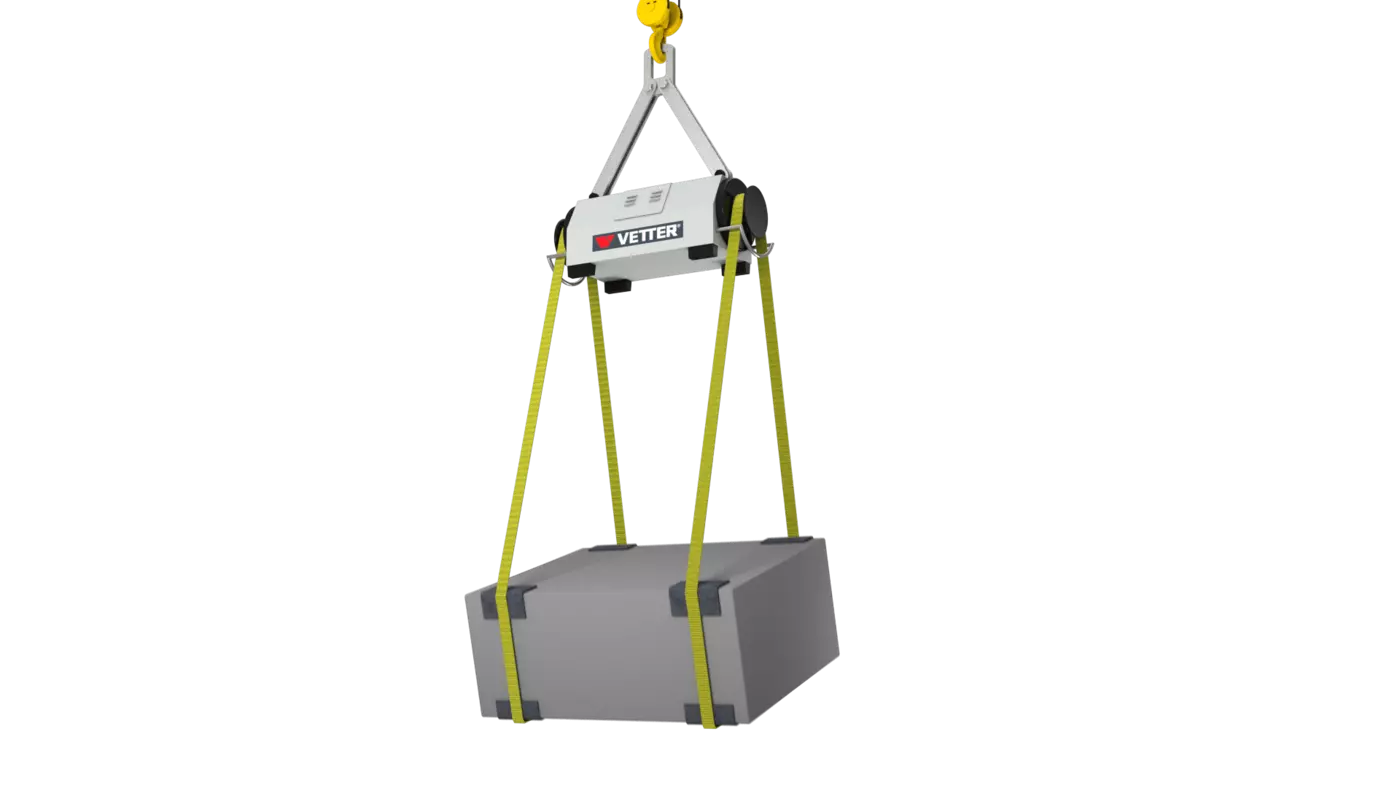

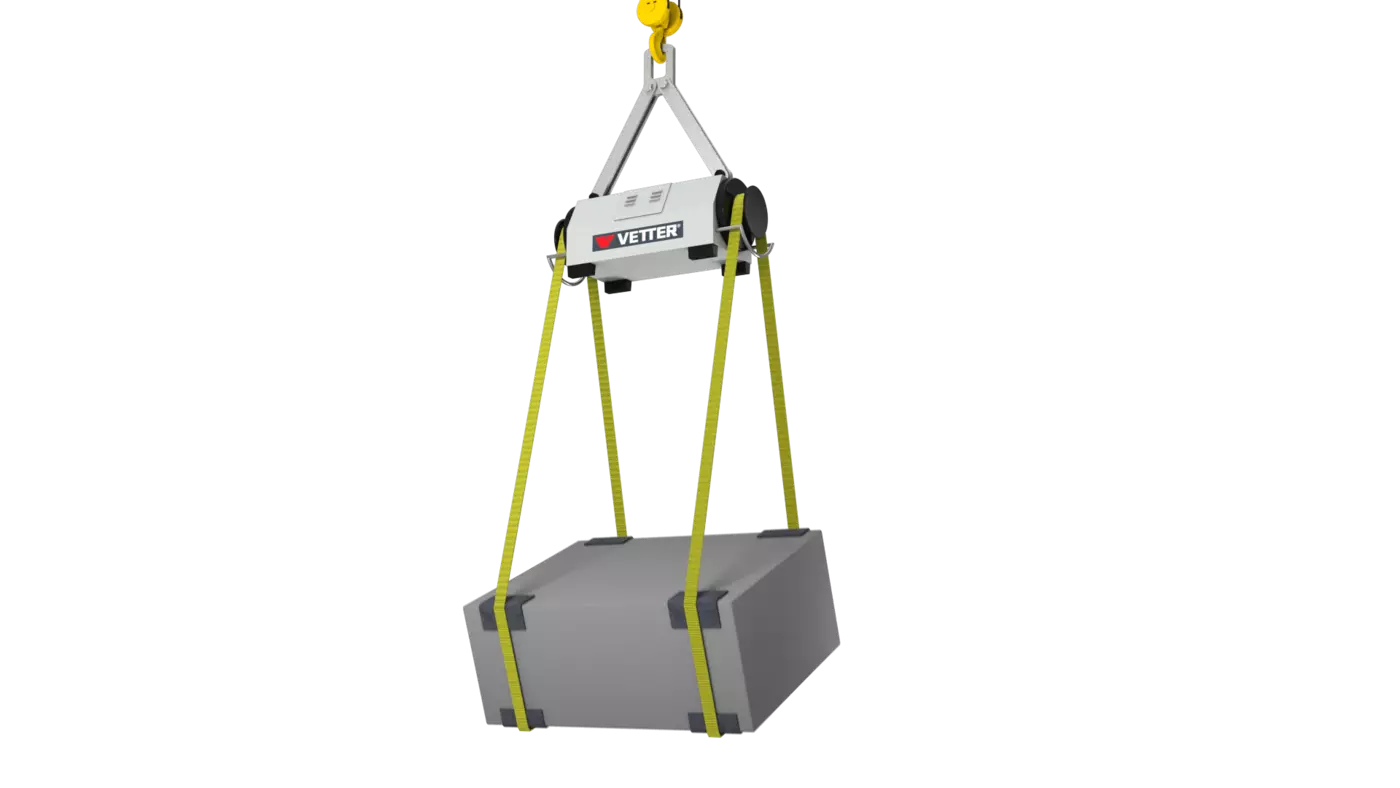

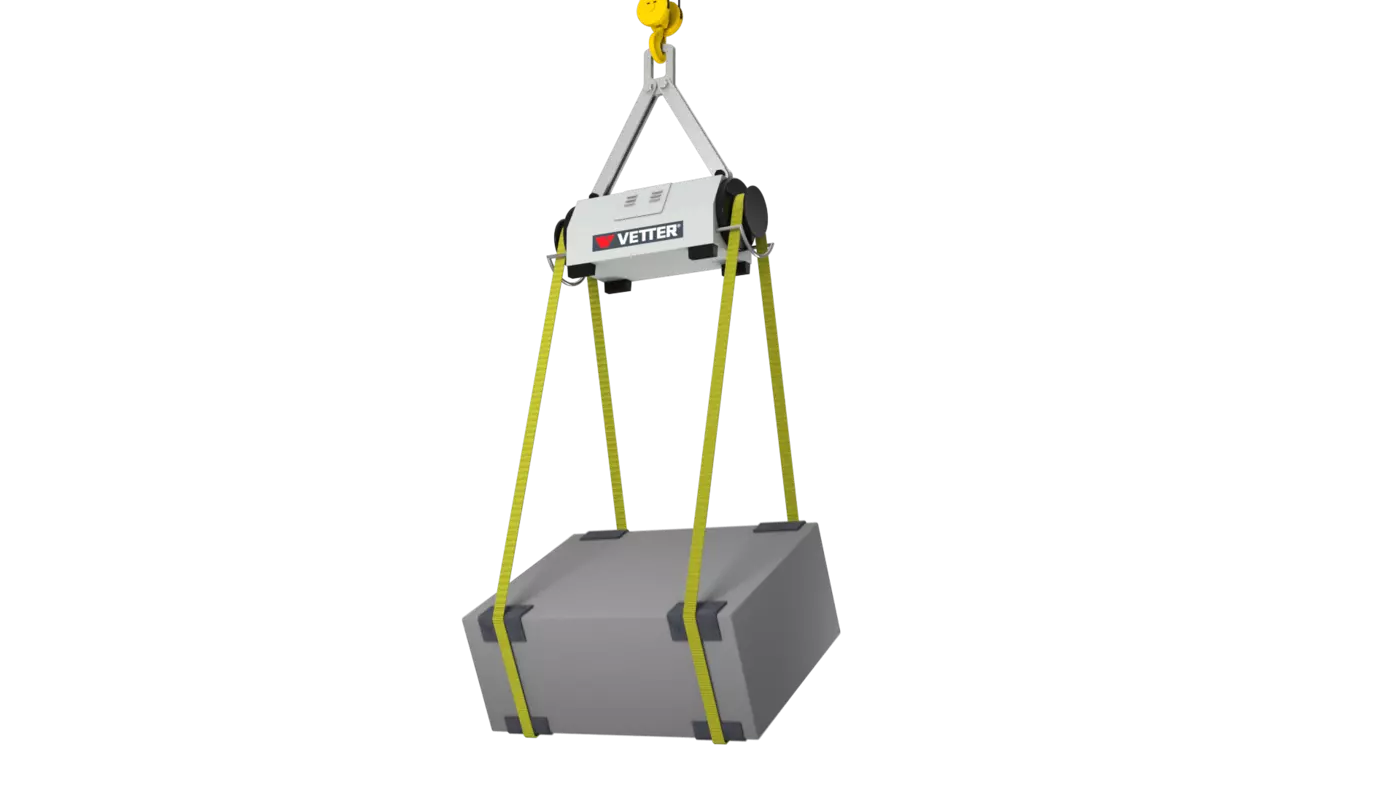

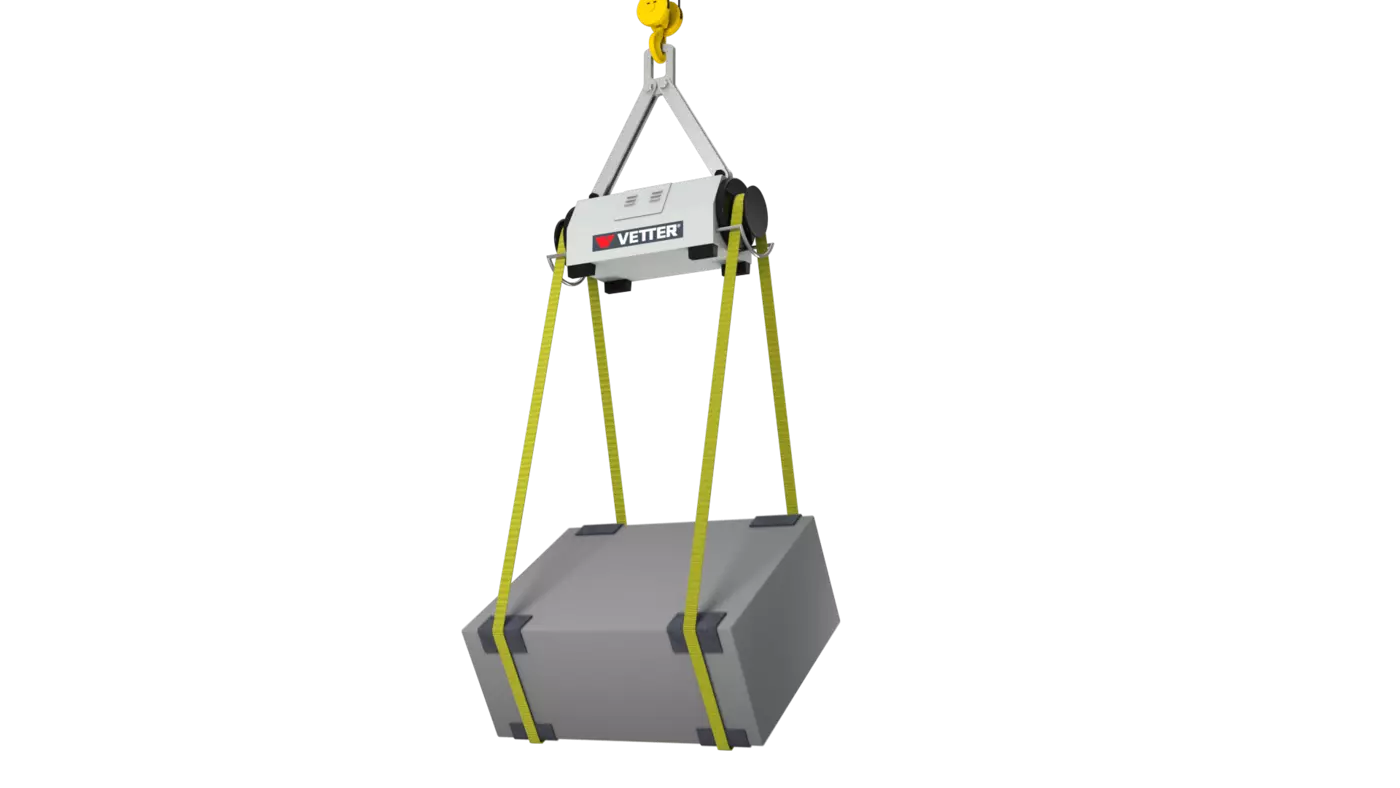

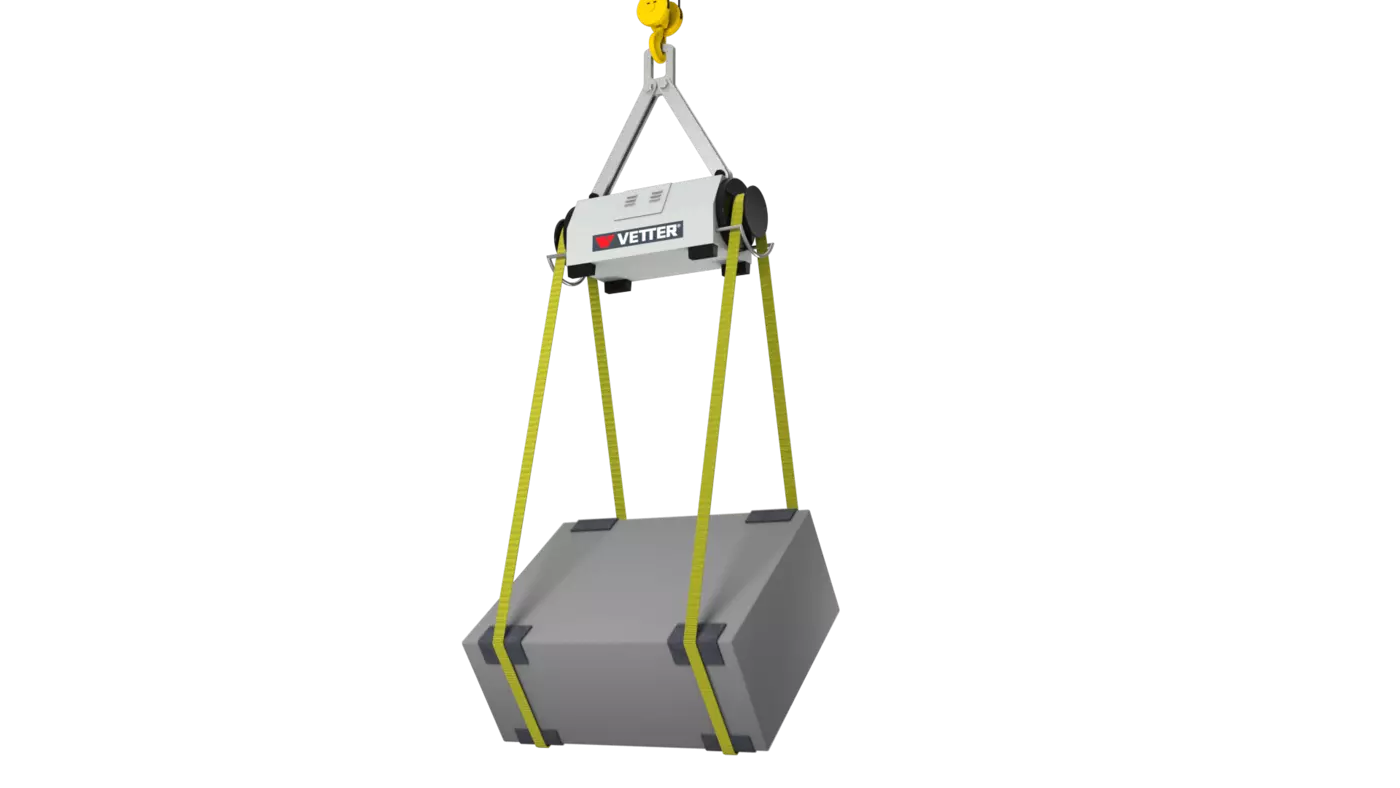

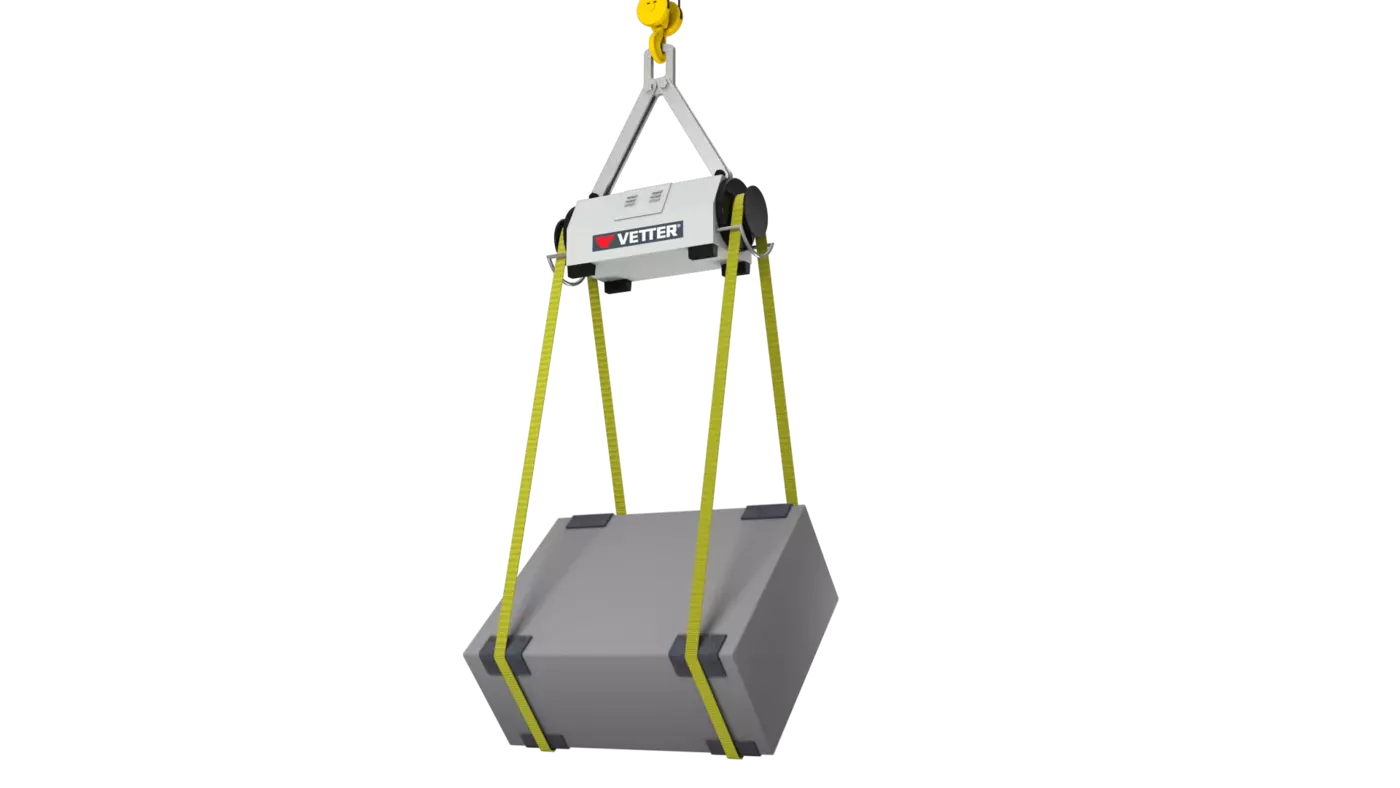

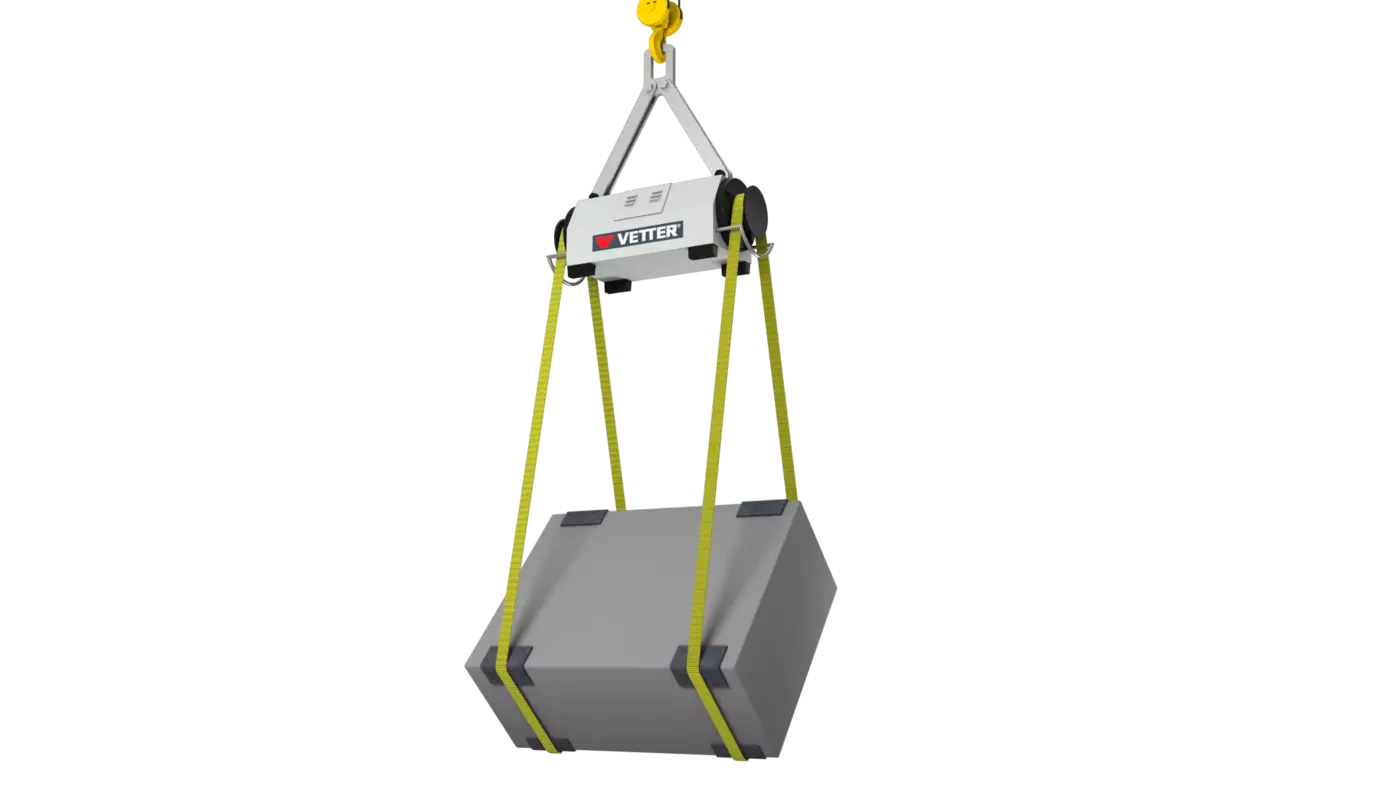

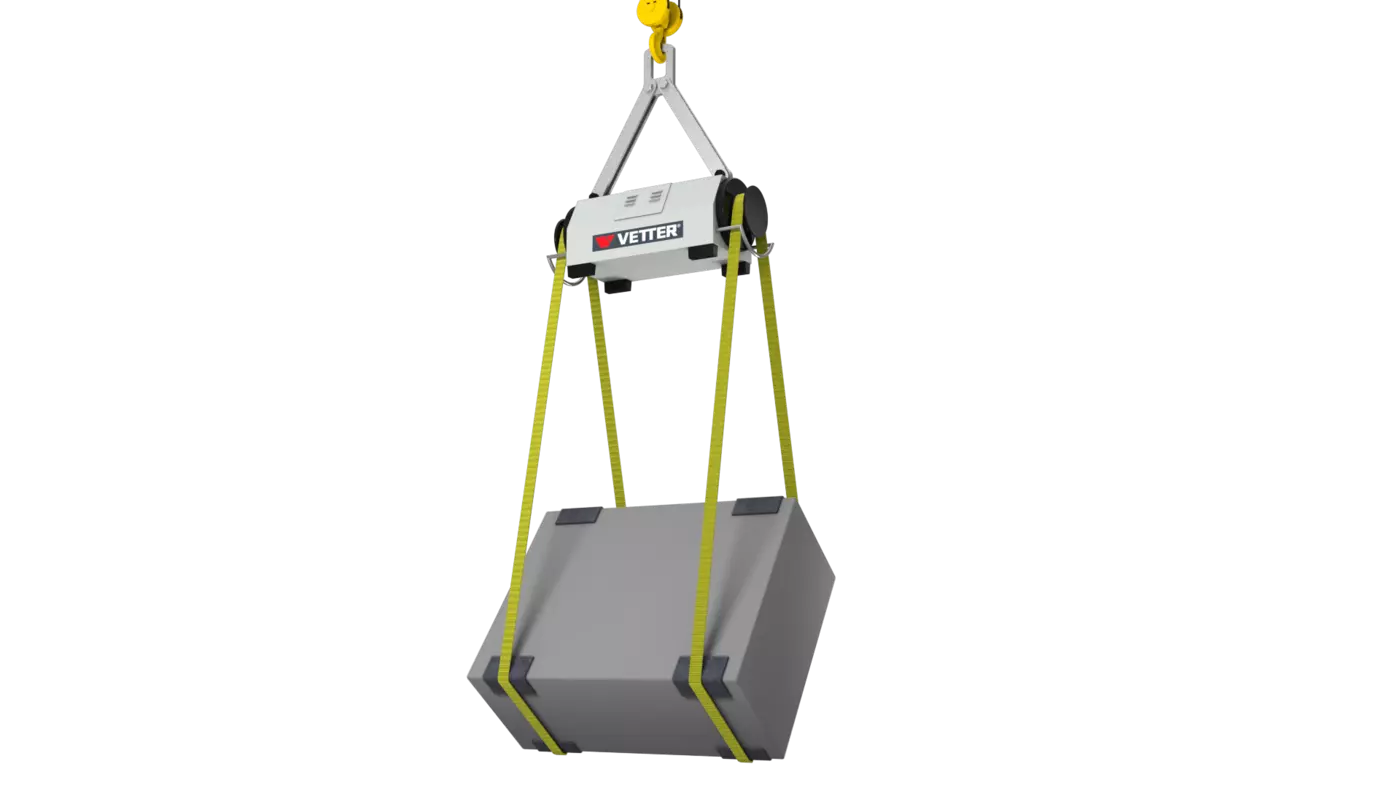

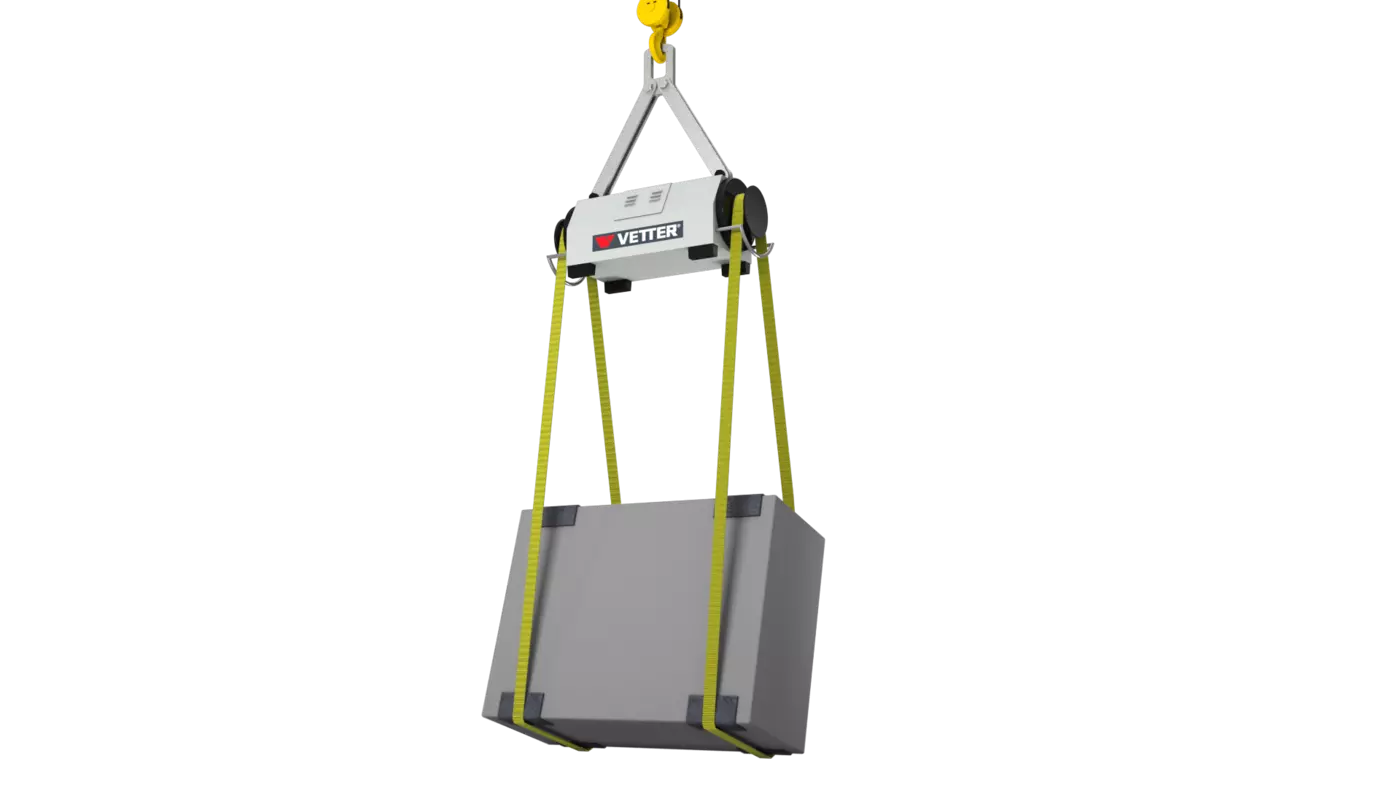

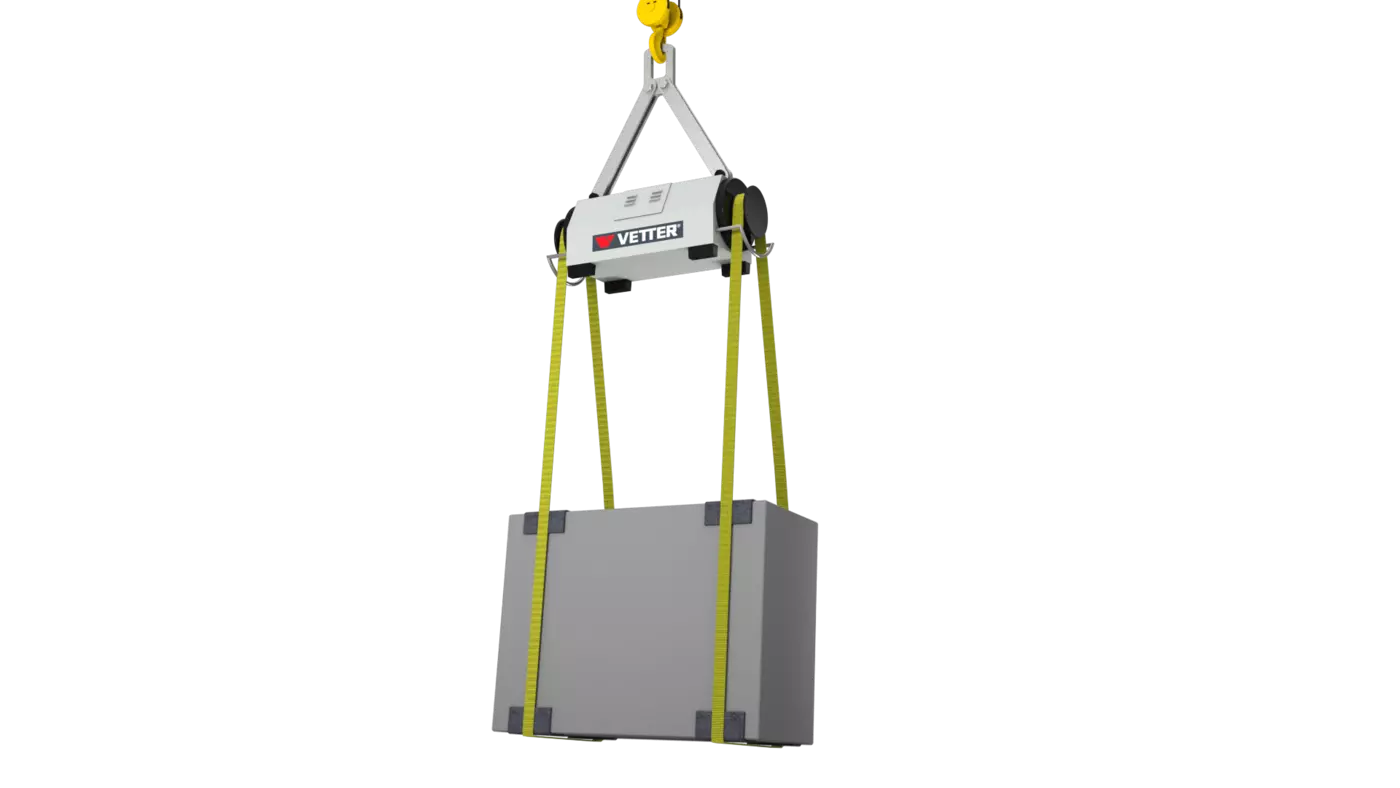

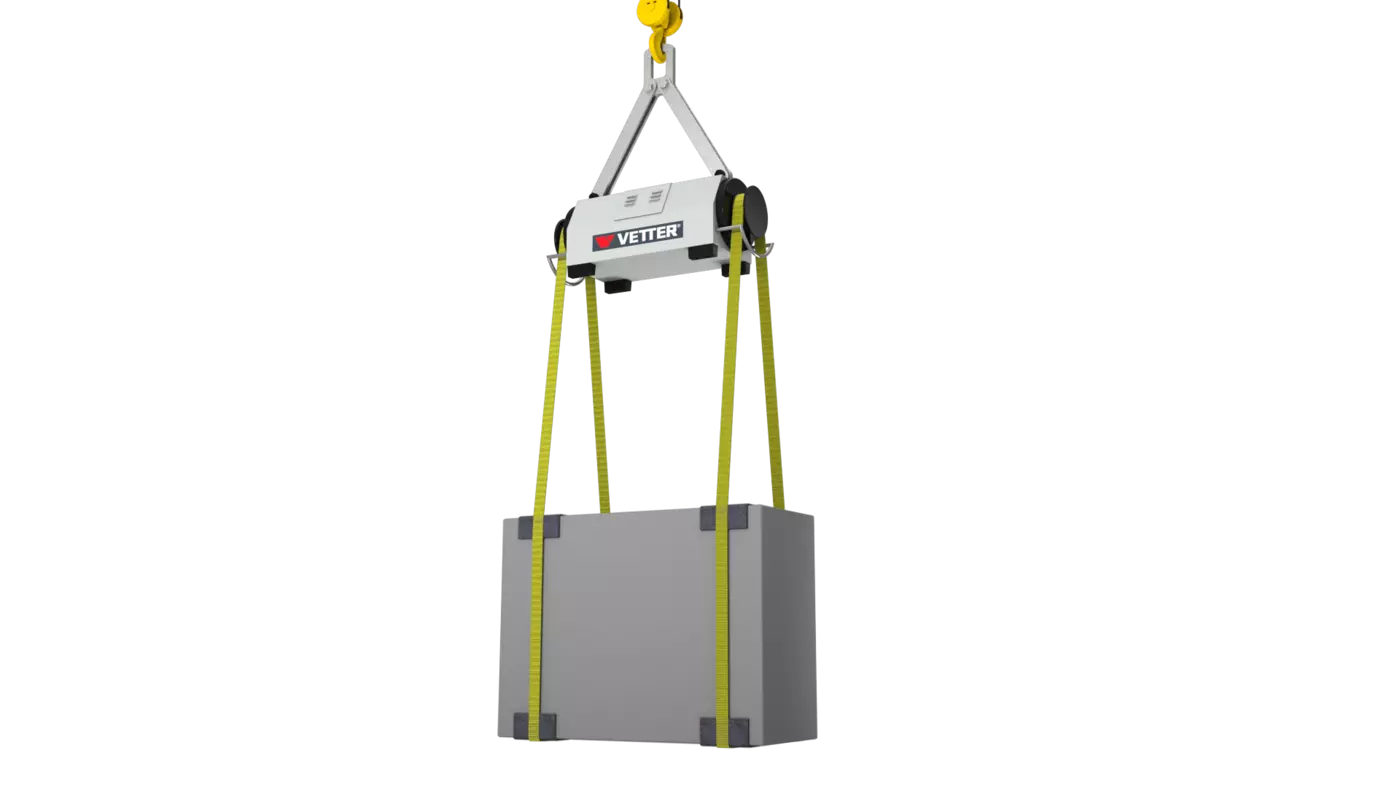

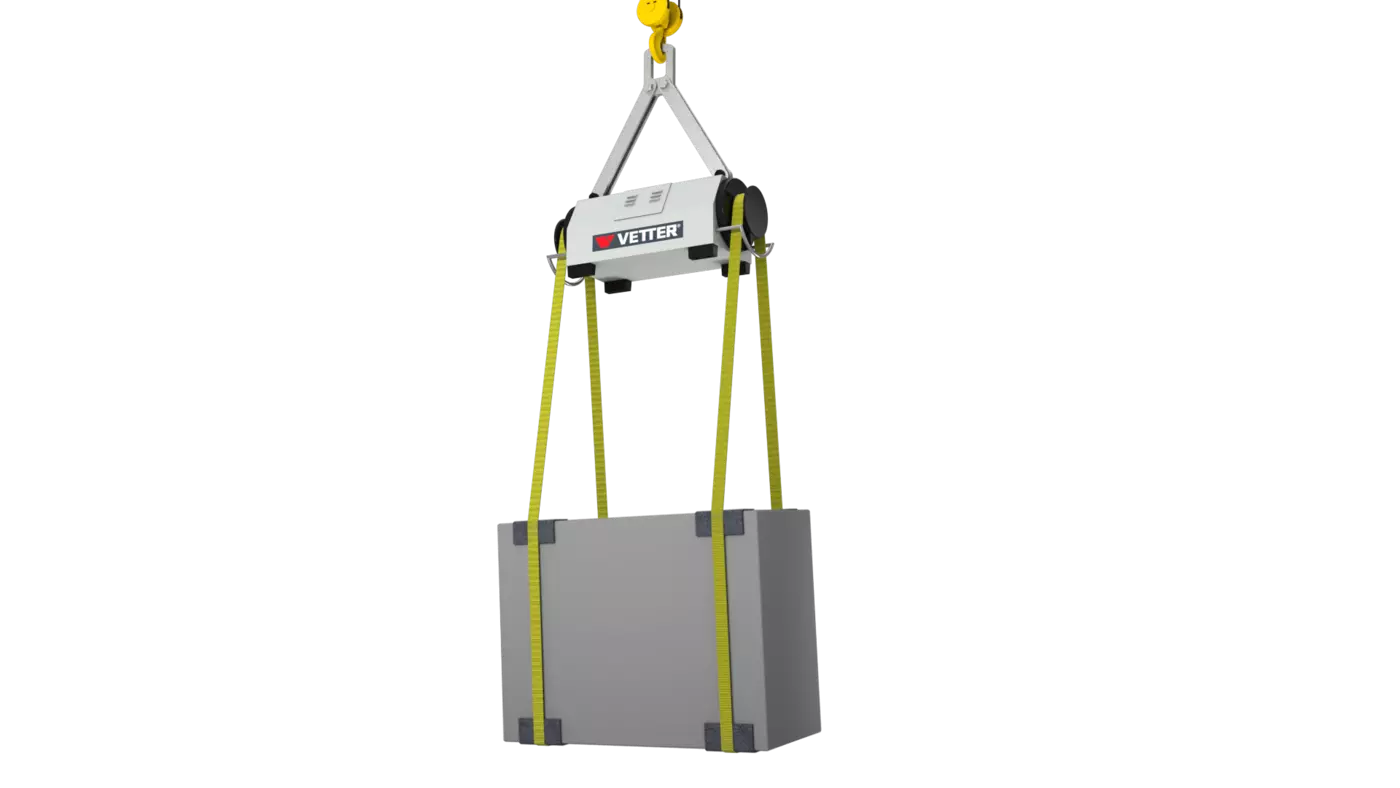

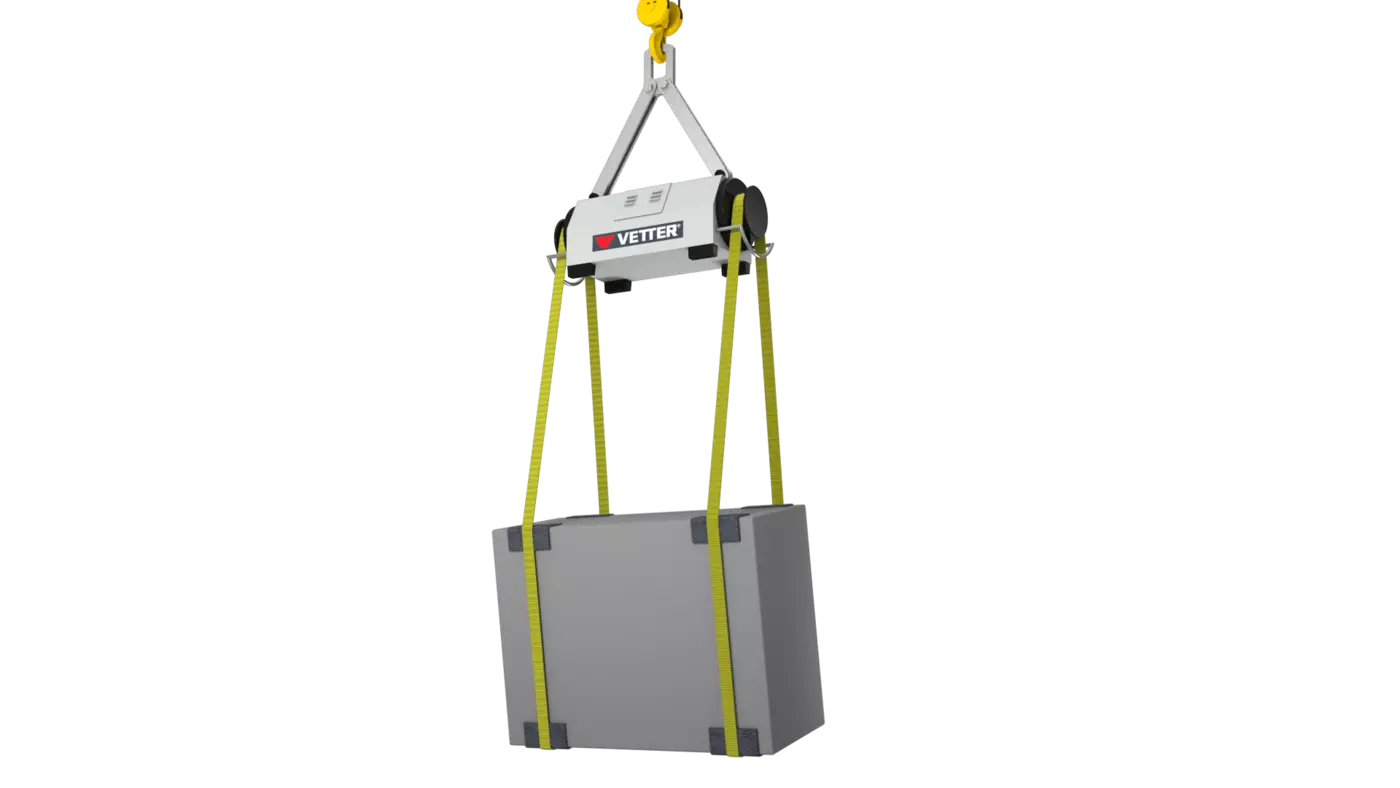

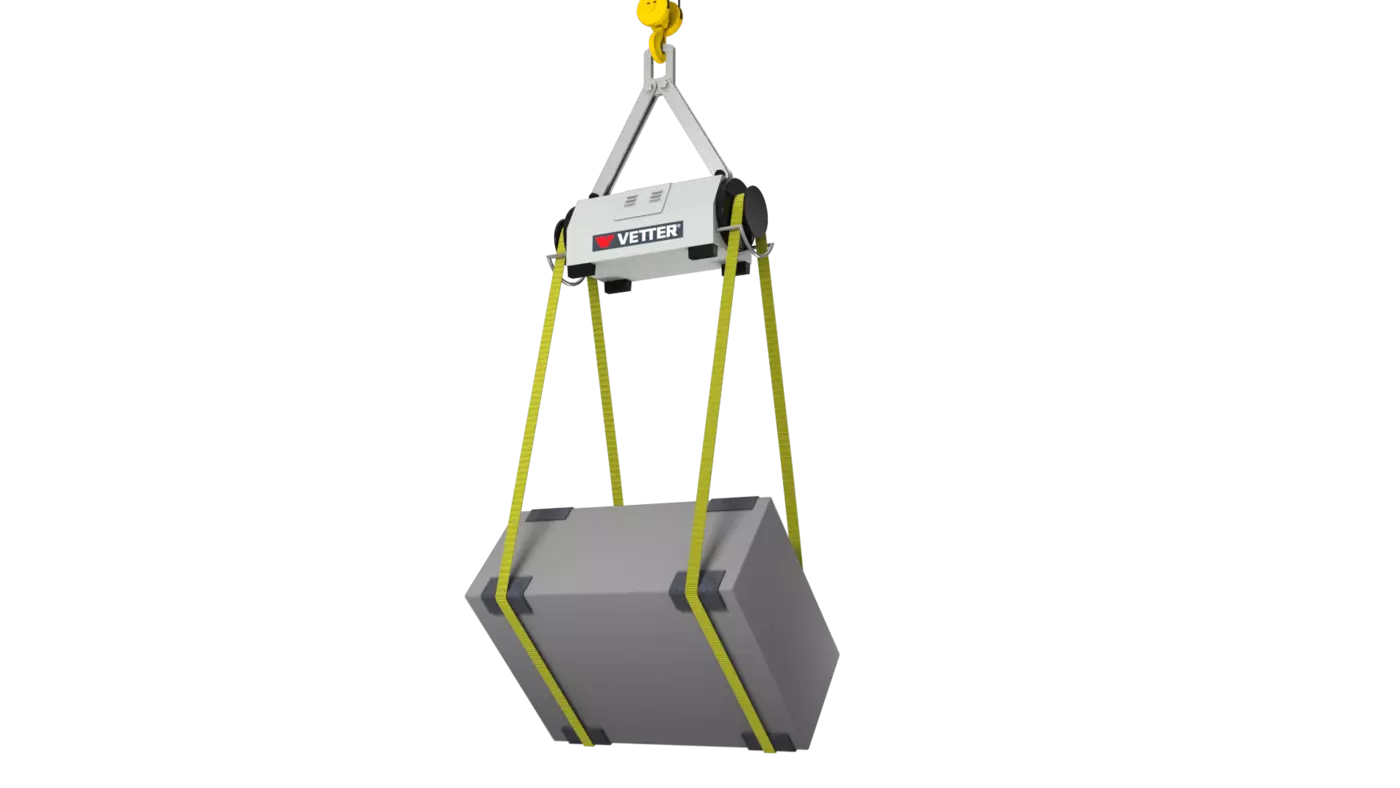

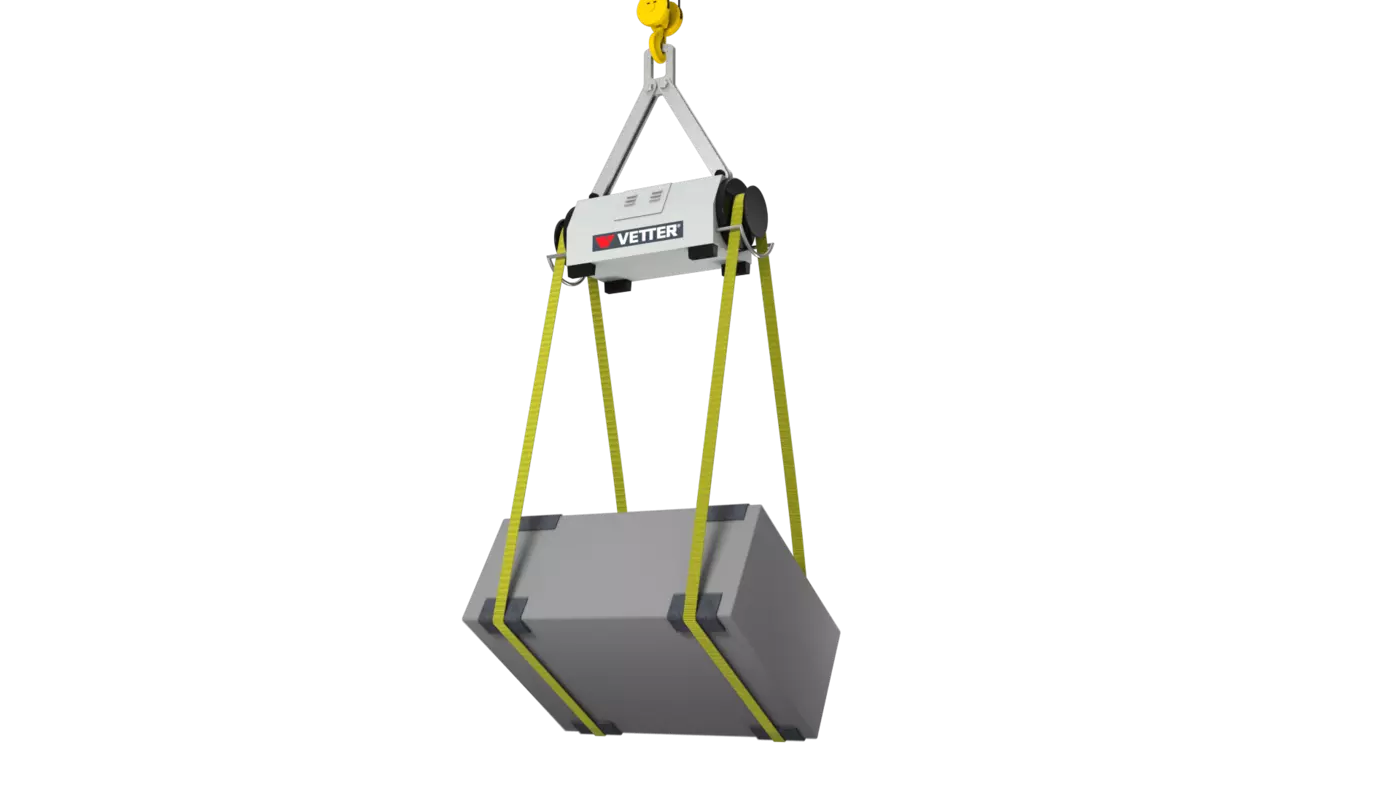

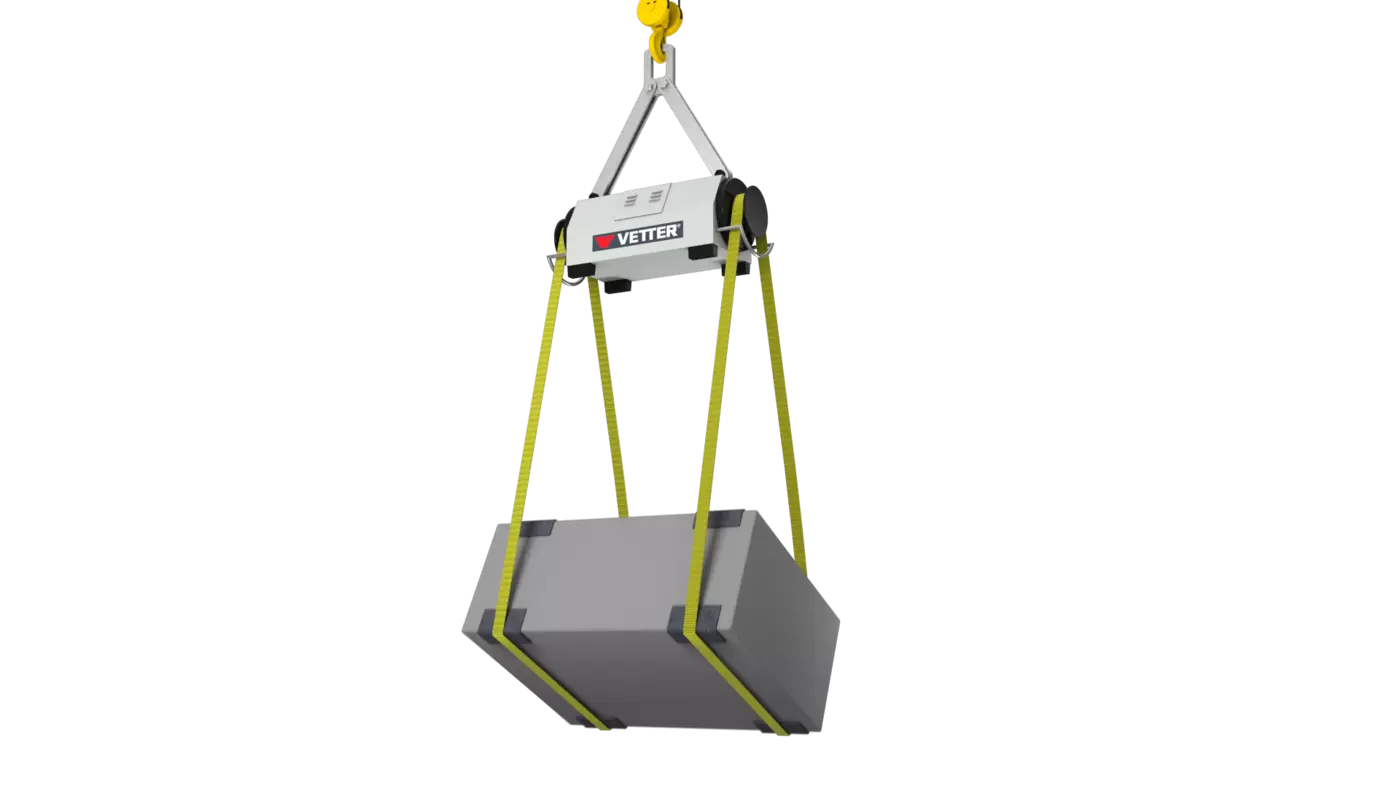

Product highlights

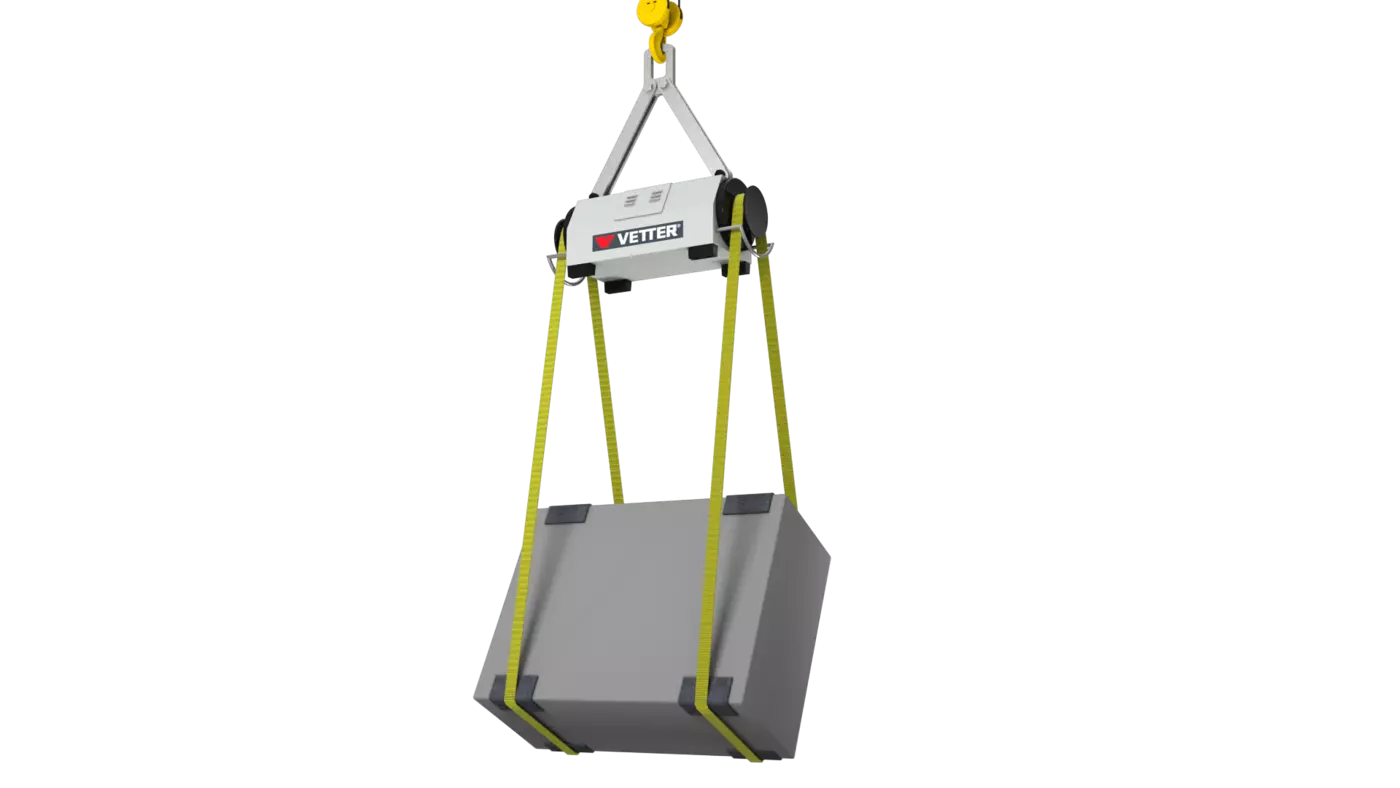

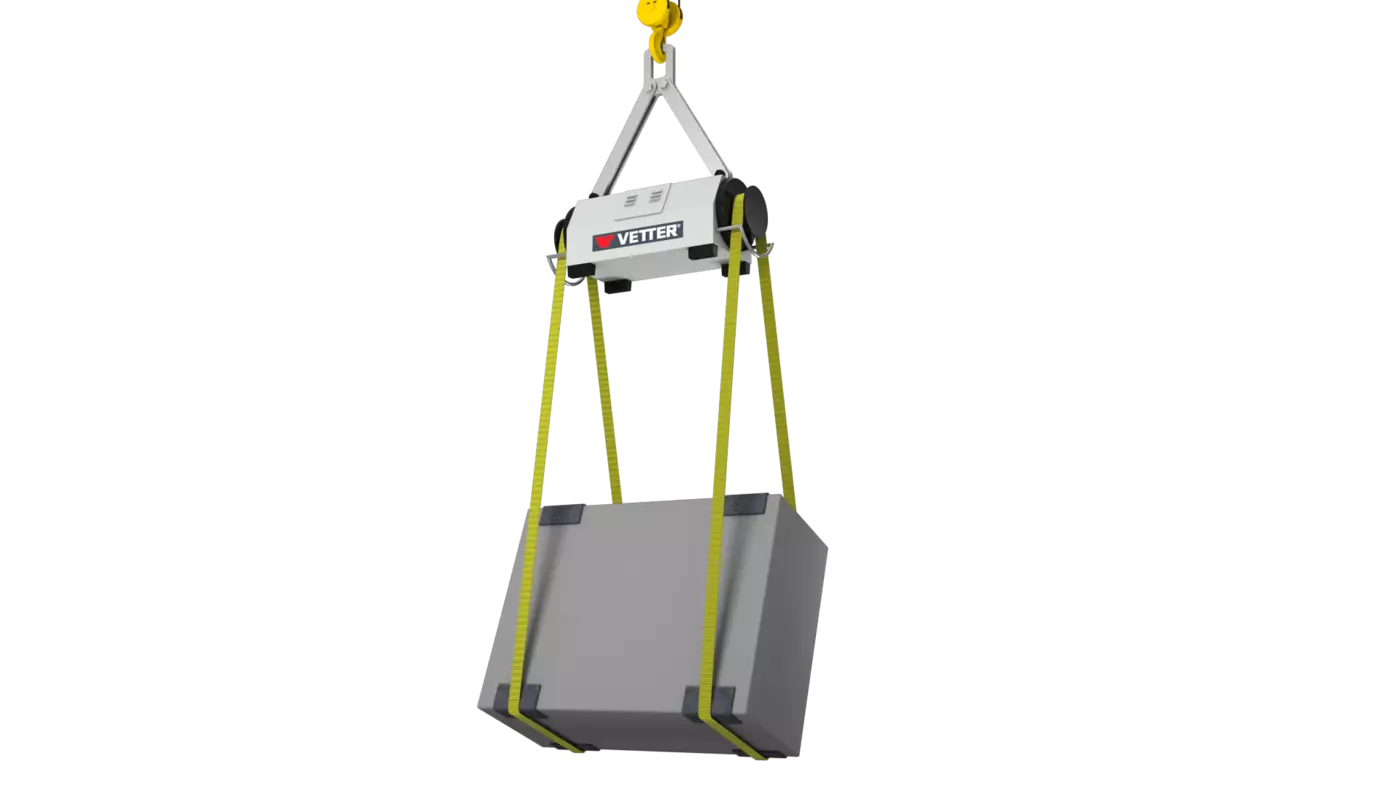

- Safe and quick turning

- Protection of components

- Operation by one person

- Comfortable operation using optional radio remote control

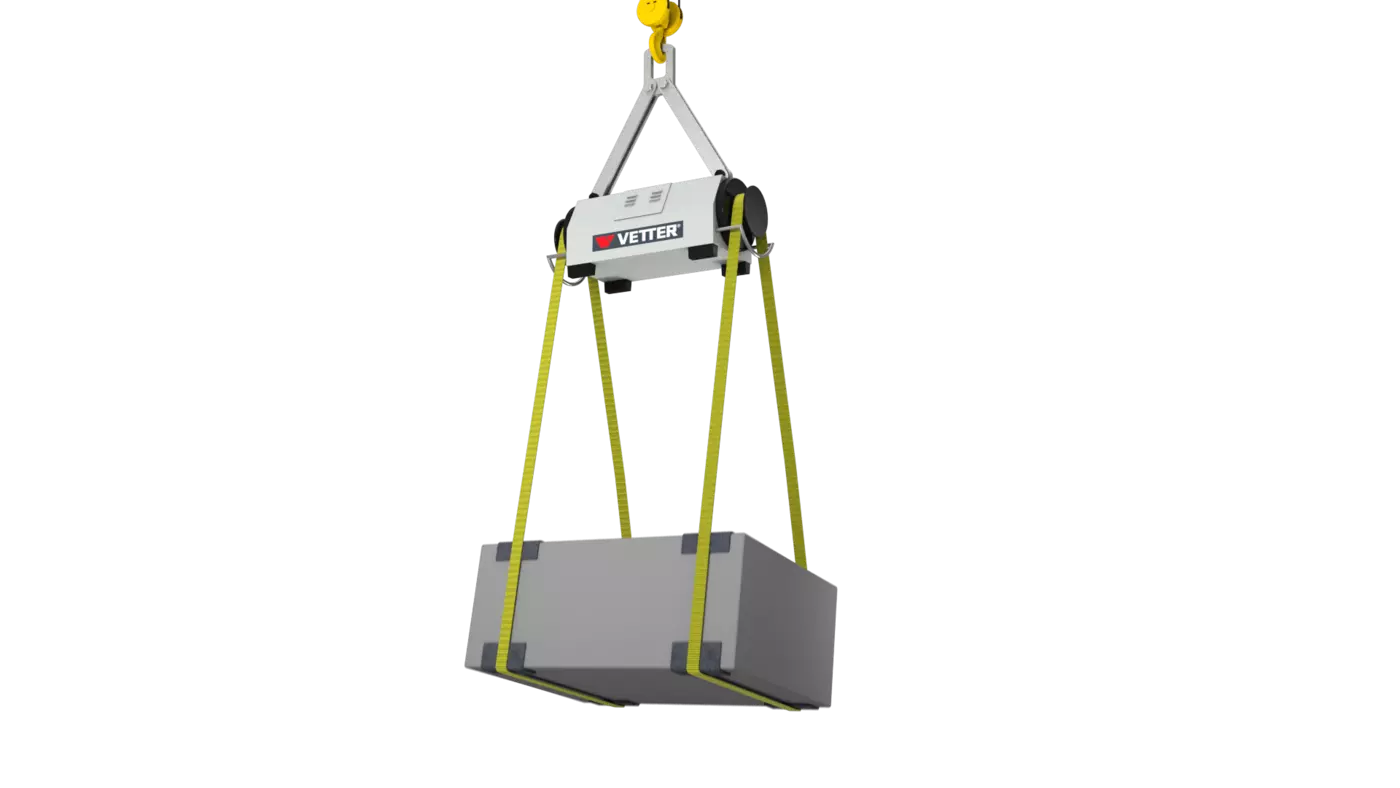

With fixed belt distance

The load turning device ROTOMAX Compact features a fixed distance between the drive wheels. A compact device which can be used where the belt distance does not need to be changed.

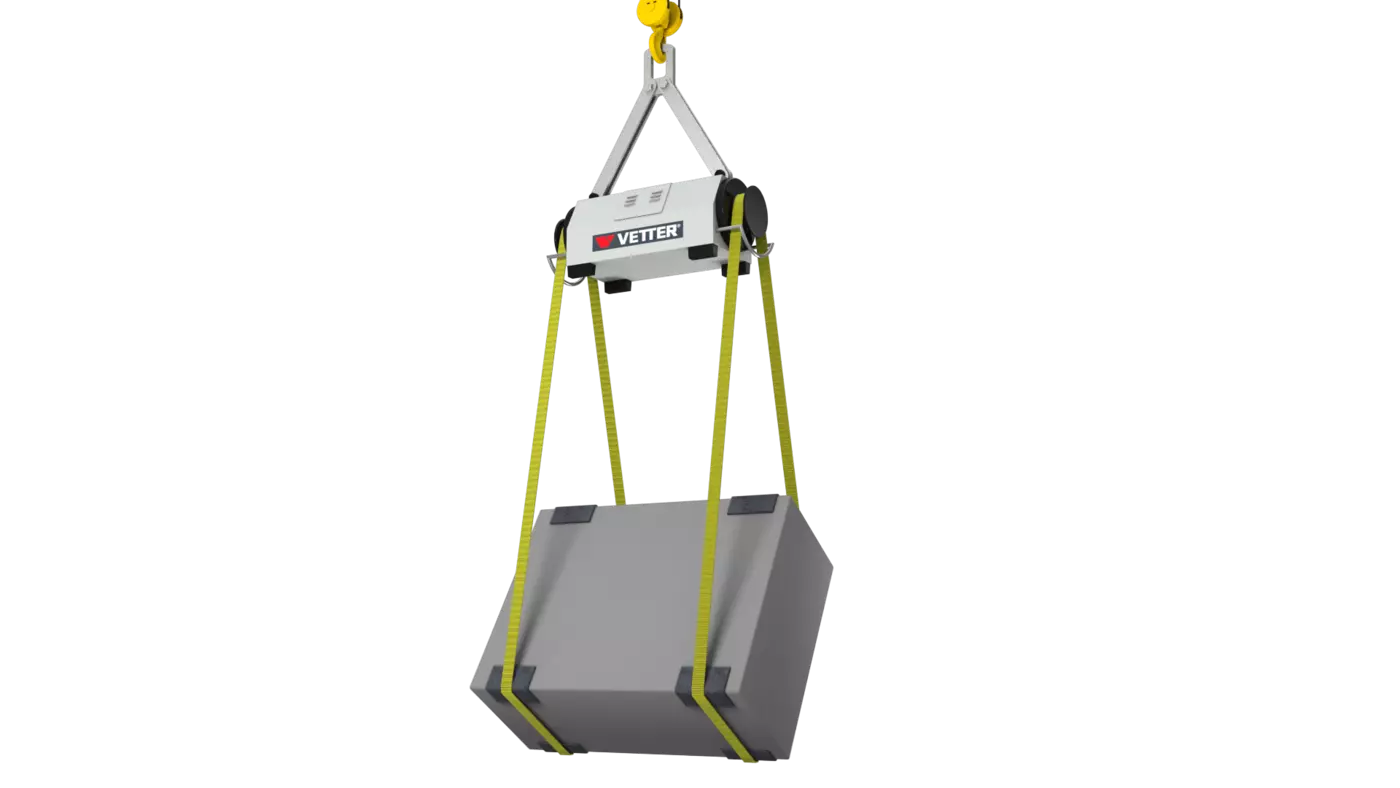

3D-Ansicht