Stadler Railgroup

The Stadler Railgroup manufactures wagons for passenger trains in Minsk. During the process of wagon body production, the large walls and roofs of the wagons are rotated.

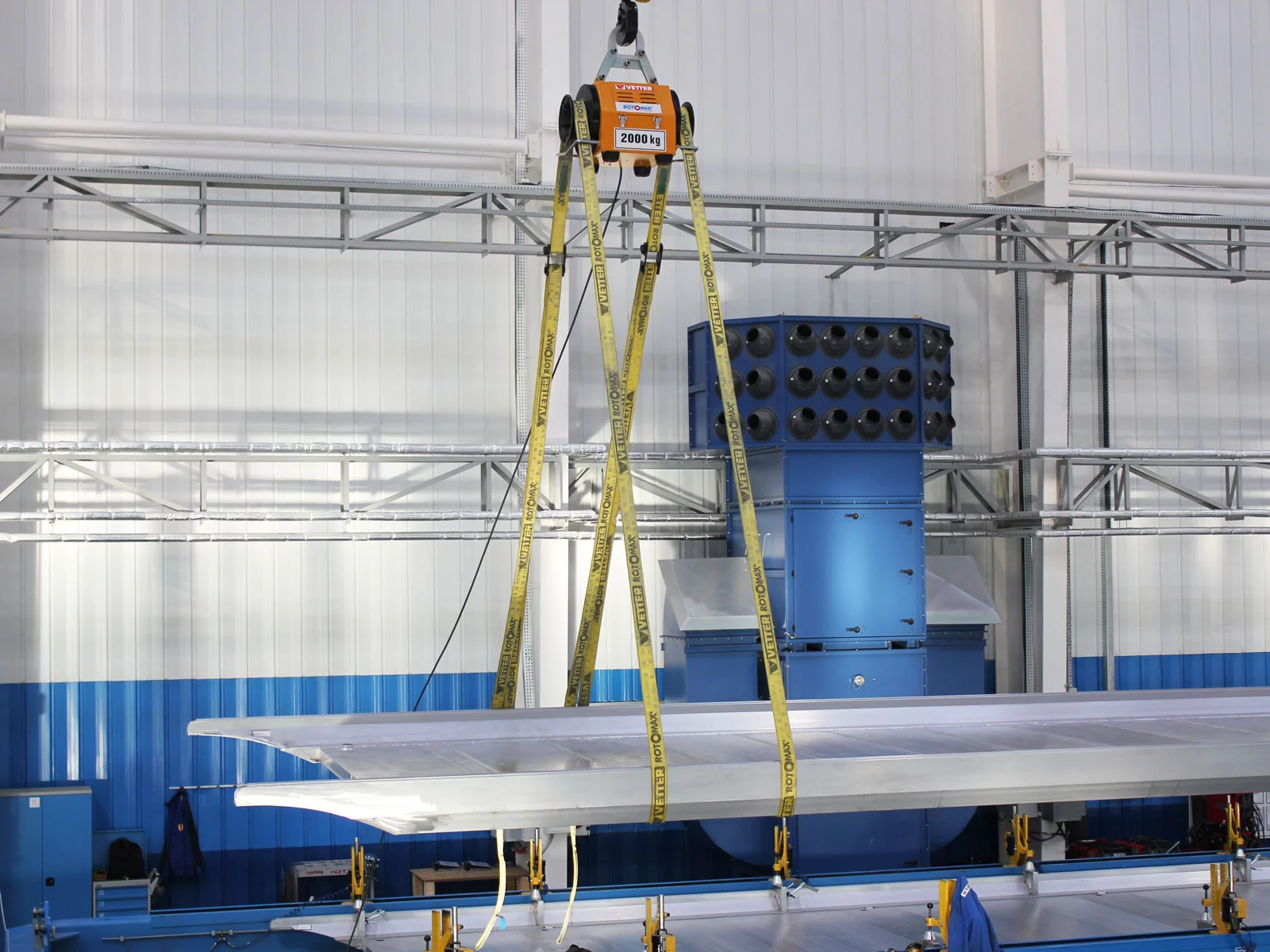

This production process is in efficient design thanks to two ROTOMAX® load turning devices by VETTER. The two devices with a capacity of 2 tons each rotate the wagon parts to their next processing position with utmost sensitivity and safety. Both devices work in tandem mode, i.e. they are controlled by one radio remote control. Accordingly, this impressive process can be controlled by a single person from a safe distance. An absolutely safe and efficient turning manoeuvre reducing the risk of damage to the expensive wagon parts to a minimum.